Getting your product specified at the Truck OE.

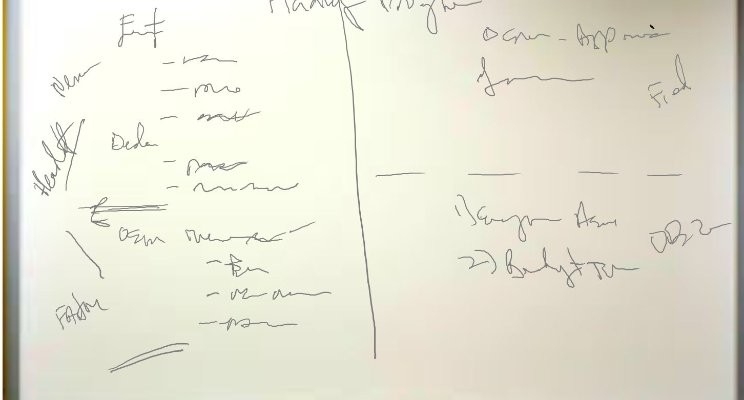

The image is a representation of our white board at the last meeting we had with Hadley, the maker of the SmartValve. (The actual had to be removed) I have been involved in helping them get their product specified, (creating a Truck Dealer option code) on new class 8 trucks. Often, the supplier's initial steps are to present the OE at the factory level and wait. Push for more attention, remind the OE about the product, present an update than more waiting. OE Truck and Trailer manufacturers plan changes out 3 to 4 years. There are a lot of moving parts to their decision process and unless they need what you are selling, it is common that you are pushed off to the next development cycle.

A better way to get your product on the truck is to go to the buyer. Not the truck OE purchasing agent or engineer but, the buyer. The fleet. The fleet also has many moving parts to their decision process but their actions are much more immediate. If you can solve a problem for a fleet, you have their attention. That is how we do it at my company, Newmarket. Engage with the fleet. The fleet manager, service manager, owner and even the driver. Identify the problem you can fix. Demonstrate the solution, test and follow up until your fleet is sold on the return for their investment.

Through selling multiple key fleets, the demand is created. Now the truck OE has a need to supply the product to a key customer. The product has been tested by the fleet. The question, “Will the fleet pay for it” has been answered and the presentations that had been made at the OE level now tie right into the OE’s development process because they need the product. A time consuming process but the right way to get it done!

For more information about the Hadley SmartValve go to Hadleyadvantage.com

Head of Sales, Idle Smart

7yGreat work, and great insight, Paul. I'm glad to hear someone else is going down this path as well! Idle Smart learned early on that the typical dealership/distributor model was not going to work well for us and our solution, so we have taken our sales efforts directly to the fleets as well. In working so closely with our end users on multiple levels (drivers, technicians, fleet managers, directors/VP's of maintenance, fuel managers, owners, etc.), we have learned so much more about their needs to make our solution a better fit for several applications. This has positioned us to demonstrate the value and the demand, take it back to OE/mod centers, and present. One thing I would add here - after successful demonstration and key fleet accounts, developing the sales channels via dealerships/mod centers is key to helping the OE see the demand. Thanks for sharing!

CEO, Newmarket Sales

7yThank you for your input Jeff. it all comes down to team work!

Sales Engineer, Strategic Account Manager | Technical Sales professional focused on solving customer business problems with unique products and services.

7yThis can work and is an effective way to drive the business. Communication with the OEM is often critical. Some systems require testing and approval from other major component suppliers due to regulations and impact on their product performance. The truck systems are far more integrated than they used to be, particularly if you are interfacing with the ECM.

Principal at NW Heavy Duty

7yGreat write-up Paul, you captured the process well. As your counterpart on the OE side of this opportunity, I would point out the importance of communicating with the vehicle OEM throughout the cycle. Engineering, Marketing, Product Planning, and Purchasing all need visibility in order to facilitate a smooth factory launch.

Congratulations Paul, Newmarket, and Hadley. The sales cycle and road to success is not always as straight as we would like. This is a great example of thinking outside the box!