Abstract

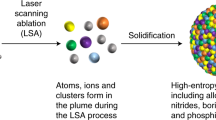

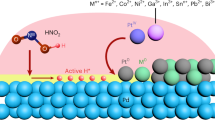

High-entropy alloy nanoparticles (HEA-NPs) show great potential as functional materials1,2,3. However, thus far, the realized high-entropy alloys have been restricted to palettes of similar elements, which greatly hinders the material design, property optimization and mechanistic exploration for different applications4,5. Herein, we discovered that liquid metal endowing negative mixing enthalpy with other elements could provide a stable thermodynamic condition and act as a desirable dynamic mixing reservoir, thus realizing the synthesis of HEA-NPs with a diverse range of metal elements in mild reaction conditions. The involved elements have a wide range of atomic radii (1.24–1.97 Å) and melting points (303–3,683 K). We also realized the precisely fabricated structures of nanoparticles via mixing enthalpy tuning. Moreover, the real-time conversion process (that is, from liquid metal to crystalline HEA-NPs) is captured in situ, which confirmed a dynamic fission–fusion behaviour during the alloying process.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper.

Code availability

The code is publicly available in the GitHub repository at https://github.com/XuhaoWan/HEA-LM.

References

Gludovatz, B. et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science 345, 1153–1158 (2014).

Li, Z., Pradeep, K. G., Deng, Y., Raabe, D. & Tasan, C. C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 534, 227–230 (2016).

Yao, Y. et al. Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359, 1489–1494 (2018).

Miracle, D. B. High entropy alloys as a bold step forward in alloy development. Nat. Commun. 10, 1805 (2019).

Feng, J. et al. Unconventional alloys confined in nanoparticles: building blocks for new matter. Matter 3, 1646–1663 (2020).

Xie, P. et al. Highly efficient decomposition of ammonia using high-entropy alloy catalysts. Nat. Commun. 10, 4011 (2019).

Li, H. et al. Fast site-to-site electron transfer of high-entropy alloy nanocatalyst driving redox electrocatalysis. Nat. Commun. 11, 5437 (2020).

Sun, Y. & Dai, S. High-entropy materials for catalysis: a new frontier. Sci. Adv. 7, eabg1600 (2021).

Gao, S. et al. Synthesis of high-entropy alloy nanoparticles on supports by the fast moving bed pyrolysis. Nat. Commun. 11, 2016 (2020).

Zhao, J. Z., Ahmed, T., Jiang, H.-X., He, J. & Sun, Q. Solidification of immiscible alloys: a review. Acta Metall. Sin. (Engl. Lett.) 30, 1–28 (2017).

Miracle, D. B. & Senkov, O. N. A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448–511 (2017).

Yang, Y. et al. Aerosol synthesis of high entropy alloy nanoparticles. Langmuir 36, 1985–1992 (2020).

Broge, N. L. N., Bondesgaard, M., Søndergaard-Pedersen, F., Roelsgaard, M. & Iversen, B. B. Autocatalytic formation of high entropy alloy nanoparticles. Angew. Chem. Int. Ed. 59, 21920–21924 (2020).

Bondesgaard, M., Broge, N. L. N., Mamakhel, A., Bremholm, M. & Iversen, B. B. General solvothermal synthesis method for complete solubility range bimetallic and high entropy alloy nanocatalysts. Adv. Funct. Mater. 29, 1905933 (2019).

Zhang, Y., Zhou, Y. J., Lin, J. P., Chen, G. L. & Liaw, P. K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 10, 534–538 (2008).

Murty, B. S., Yeh, J. W., Ranganathan, S. & Bhattacharjee, P. P. High-Entropy Alloys (Elsevier, 2019).

Si, J. et al. Chemical potential-modulated ultrahigh-phase-purity growth of ultrathin transition-metal boride single crystals. J. Am. Chem. Soc. 145, 3994–4002 (2023).

Chen, Y. et al. Growth of 2D GaN single crystals on liquid metals. J. Am. Chem. Soc. 140, 16392–16395 (2018).

Markvicka, E. J., Bartlett, M. D., Huang, X. & Majidi, C. An autonomously electrically self-healing liquid metal-elastomer composite for robust soft-matter robotics and electronics. Nat. Mater. 17, 618–624 (2018).

Zavabeti, A. et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science 358, 332–335 (2017).

Wang, W., Zhu, X. & Fu, L. Touch ablation of lithium dendrites via liquid metal for high-rate and long-lived batteries. CCS Chem. 2, 686–695 (2020).

Esrafilzadeh, D. et al. Room temperature CO2 reduction to solid carbon species on liquid metals featuring atomically thin ceria interfaces. Nat. Commun. 10, 865 (2019).

Tang, J., Zhao, X., Li, J. & Liu, J. Thin, porous, and conductive networks of metal nanoparticles through electrochemical welding on a liquid metal template. Adv. Mater. Interfaces 5, 1800406 (2018).

Takeuchi, A. & Inoue, A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 46, 2817–2829 (2005).

Yao, Y. et al. Computationally aided, entropy-driven synthesis of highly efficient and durable multi-elemental alloy catalysts. Sci. Adv. 6, eaaz0510 (2020).

Chang, X., Zeng, M. & Fu, L. Phase engineering of high-entropy alloys. Adv. Mater. 32, 1907226 (2020).

Niu, H., Bonati, L., Piaggi, P. & Parrinello, M. Ab initio phase diagram and nucleation of gallium. Nat. Commun. 11, 2654 (2020).

Zhao, L., Zong, H., Ding, X. & Lookman, T. Anomalous dislocation core structure in shock compressed bcc high-entropy alloys. Acta Mater. 209, 116801 (2021).

Yamaguchi, A., Mashima, Y. & Iyoda, T. Reversible size control of liquid-metal nanoparticles under ultrasonication. Angew. Chem. Int. Ed. 54, 12809–12813 (2015).

Cutinho, J. et al. Autonomous thermal-oxidative composition inversion and texture tuning of liquid metal surfaces. ACS Nano 12, 4744–4753 (2018).

Martin, A., Kiarie, W., Chang, B. & Thuo, M. Chameleon metals: autonomous nano-texturing and composition inversion on liquid metals surfaces. Angew. Chem. Int. Ed. 59, 352–357 (2020).

Daeneke, T. et al. Liquid metals: fundamentals and applications in chemistry. Chem. Soc. Rev. 47, 4073–4111 (2018).

Zhang, L. et al. End-to-end symmetry preserving inter-atomic potential energy model for finite and extended systems. In Proc. 32nd International Conference on Neural Information Processing Systems (ed. Bengio, S. et al.) 4441–4451 (Curran Associates, 2018).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Acknowledgements

We thank the Core Facility of Wuhan University for providing the inductively coupled plasma–atomic emission spectrometry tests. We also thank the Core Research Facilities of the College of Chemistry and Molecular Sciences at Wuhan University for the SEM characterization, the Shanghai Synchrotron Radiation Facility for the in situ X-ray diffraction and the Center for Electron Microscopy at Wuhan University for their substantial support of transmission electron microscopy characterization. The research was supported by the National Natural Science Foundation of China (Grants 22025303, 21905210 and 11974156); the National Youth Talent Support Program; the Inner Mongolia Natural Science Foundation (Grant 2019MS02006); the Program for Young Talents of Science and Technology in Universities of Inner Mongolia Autonomous Region (Grant NJYT-20-B10); the Guangdong Innovative and Entrepreneurial Research Team Program (Grant 2019ZT08C044); the Shenzhen Science and Technology Program (Grants KQTD20190929173815000 and 20200925161102001); and the Science, Technology and Innovation Commission of Shenzhen Municipality (Grant ZDSYS20190902092905285). We also received assistance from the SUSTech Core Research Facilities, especially technical support from Pico Centre, which receives support from the Presidential Fund and the Development and Reform Commission of Shenzhen Municipality.

Author information

Authors and Affiliations

Contributions

L.F. conceived the research concept. L.F. and M.Q.Z. supervised the research. G.H.C., J. Liang and K.N.Y. carried out the main experiments. J. Lin, Z.G., G.W. and Y.F. performed transmission electron microscopy characterizations. Y.G., X.W. and Z. Li contributed to theoretical calculation. Y.B. conducted the Rietveld refinement. H.W., Y.Z., J. Liu, G.H. and Z.X. contributed to sample preparation. L.F., M.Z., G.C., J. Liang and K.Y. cowrote the manuscript. All the authors contributed to data analysis and scientific discussion.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Liangbing Hu, Yong Yang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 The TEM EDS mapping of the precursor with adjacent Ga NPs.

The metal salts are uniformly distributed around Ga NPs. There is a clear boundary between metal salts and Ga NPs. Moreover, the contrast of Cu elemental mapping could be affected by the copper grid.

Extended Data Fig. 3 STEM elemental maps of octonary (GaMnNiCuRuRhFeCo), novenary (GaCuPdNiMnInRhPtCo), and 17 (GaFeNiCuZnScVMnMgZrPtRhRuIrHfMoNb) HEA-NPs, respectively.

All HEA-NPs exhibit uniform element distribution.

Extended Data Fig. 4 Elemental characterization of HEA-NPs with different diameters.

a, STEM elemental maps of the HEA-NPs (GaCaCoNiCu) with different sizes of about 50 nm, 75 nm, and 100 nm, respectively. b, STEM elemental maps of the HEA-NPs (GaCuPdNiMnAlInRhPtCoMg) with different sizes of about 15 nm, 40 nm, and 75 nm, respectively. All HEA-NPs exhibited uniform elemental distribution.

Extended Data Fig. 8 TEM characterization of an individual GaFeMnNiCu nanoparticle after in situ reaction.

a, TEM image and FFT analysis (inset) of the nanoparticle, showing the occurrence of crystallization. b, The EDS mapping of the nanoparticle. The uniform elemental distribution indicates the elements can be alloyed into a nanoparticle by the in situ reaction process.

Supplementary information

Supplementary Information

Supplementary Figs. 1–34, Tables 1–10 and References.

Supplementary Video 1

The dynamic fusion process of nanoparticles during the in situ experiment.

Supplementary Video 2

The dynamic fusion–fission process of nanoparticles during the in situ experiment; the nanoparticles merge during heating, and moreover, the fission process is captured at the interval from 5.32 to 5.46 s.

Source data

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cao, G., Liang, J., Guo, Z. et al. Liquid metal for high-entropy alloy nanoparticles synthesis. Nature 619, 73–77 (2023). https://doi.org/10.1038/s41586-023-06082-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-023-06082-9

This article is cited by

-

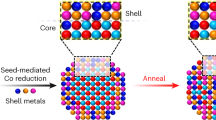

Retrosynthetic design of core–shell nanoparticles for thermal conversion to monodisperse high-entropy alloy nanoparticles

Nature Synthesis (2023)

-

Microstructure Evolution and Tensile Properties of the Alx(CoCrNi)100-x Medium-Entropy Alloys

Acta Metallurgica Sinica (English Letters) (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.