Bill Acceptor

Bill Acceptor

Bill Acceptor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Bill</strong> <strong>Acceptor</strong><br />

DBV-30X-SU<br />

DBV-30X-SD<br />

Note<br />

1. It is fobridden to copy the contents of this manual, in whole or in part,<br />

except for the user’s personal use, without the express permission of<br />

Japan Cash Machine Co., Ltd.<br />

2. The information provided in this manual is subject to change without<br />

notice.<br />

3. This manual has been written with care and attention to detail; however,<br />

should you find any errors or omissions, please contact Japan Cash<br />

machine Co., Ltd. and inform tem of you findings.<br />

4. Please be aware that Japan Cash Machine shall not be held liable by the<br />

user for any damages, losses or third party claims arising from any uses<br />

of this product.<br />

5. All Company/Manufacturer names used in this manual are the registered<br />

trademarks of those companies.<br />

Issue 03/2006<br />

Copyright © 2005 Japan Cash Machine Co.Ltd. All rights reserved.

Preface/Documentation Conventions etc.<br />

Preface<br />

Thank you for purchasing the Japan Cash Machine <strong>Bill</strong> Accepter DBV-30X-SU/DBV-30X-SD (here after<br />

referred to as the “DBV-30X unit”). Please read this manual carefully as it explains, step by step, how to<br />

use the DBV-30X correctly and safely. Be sure to read this manual and any related materials thoroughly<br />

to understand the correct operation and functions of this unit.<br />

Documentation Conventions<br />

The list below describes the documentation convertions used in this manual.<br />

This icon indicates situations where slight bodily injury or equipment<br />

damage can occur.<br />

This icon indecates important information or procedures that must be<br />

followed for correct and risk-free unit operation.<br />

This icon indicates useful or recommended supplemental<br />

information.<br />

1), 2)<br />

This indicates steps in a procedure. Be sure to perform these steps in<br />

the order given.<br />

* This indicates useful or important supplemental information<br />

CE Marking Notes<br />

The DBV-301-SU is CE marked products.<br />

•Complies with the following Standard.<br />

EN61000-6-1: 2001 EN61000-4-2: 1995+A1 : 1998+A2 : 2001<br />

EN61000-4-3 : 2002+A1 : 2002<br />

EN61000-6-3 : 2001 EN55022 : 1998 (ClassB)<br />

2

Package Contents/Version Information<br />

Package Contents<br />

The DBV-30X unit’s packing box contains theitems listed below. Please check to confirm that all items<br />

shown below have been included.<br />

•DBV-30X-SX unit (1) •Harness (1)<br />

MDB Harness (EDP#: 128233) or<br />

Optional Harness (EDP#: 108233)<br />

MDB Harness<br />

Optional Harness<br />

Model and Serial No. Information<br />

To identify your DBV-30X unit’s model and serial number, see the metallic label attached to the left side<br />

of DBV-30X unit.<br />

MODEL DBV-301-SU-USA2-2111-D3<br />

SERIAL NO.* * * * * * * * * *<br />

DC 24-36V 0.9-0.6A<br />

MADE IN JAPAN<br />

3

Table of Contents<br />

Table of Contents<br />

CHAPTER 1<br />

Model Numbers and Specifications<br />

1-1. Precautions .............................................................................. 1-2<br />

1-2. Main Features........................................................................... 1-3<br />

1-2-1. Intelligent 3-way LED for Easy field Diagnosis .................................1-3<br />

1-2-2. Palm Programmable............................................................................1-3<br />

1-2-3. Built in Auditing Functions.................................................................1-3<br />

1-2-4. Optional <strong>Bill</strong> Recycler (RC-10) ...........................................................1-3<br />

1-3. DBV-30X Naming Composition ............................................... 1-4<br />

1-3-1. Model ....................................................................................................1-4<br />

1-3-2. Type ......................................................................................................1-4<br />

1-4. Component Names .................................................................. 1-5<br />

1-5. System Configuration.............................................................. 1-6<br />

1-5-1. DBV-301 System Configuration..........................................................1-6<br />

1-5-1. DBV-302 System Configuration..........................................................1-7<br />

1-6. Specifications .......................................................................... 1-8<br />

1-6-1. Technical Specifications .....................................................................1-8<br />

1-6-2. Environmental Specifications ............................................................1-8<br />

1-6-3. Electrical Specifications .....................................................................1-9<br />

1-6-4. Structural Specifications ....................................................................1-9<br />

1-7. Interface Connector and Pin Assignment............................ 1-10<br />

1-7-1. When using ID-0D3 Interface ............................................................1-10<br />

1-7-2. When using ID-003 Interface ............................................................1-12<br />

1-8. DIP Switch Settings ............................................................... 1-14<br />

1-8-1. DIP Switch 1 (SW1)............................................................................ 1-14<br />

1-8-2. DIP Switch 2 (SW2)............................................................................ 1-15<br />

1-9. Dimensions ............................................................................ 1-16<br />

1-9-1. DBV-30X-SU with 200 notes cash box ............................................. 1-16<br />

1-9-2. DBV-30X-SU with 300 notes cash box ............................................. 1-17<br />

1-9-3. DBV-30X-SU with 1,000 notes cash box .......................................... 1-18<br />

1-9-4. DBV-30X-SD with 200 notes cash box ............................................. 1-19<br />

1-9-5. DBV-30X-SD with 300 notes cash box ............................................. 1-20<br />

1-9-6. DBV-30X-SD with 1,000 notes cash box .......................................... 1-21<br />

4

Table of Contents<br />

CHAPTER 2<br />

Installation and Operation<br />

2-1. Installation ................................................................................ 2-2<br />

2-1-1. Installation ...........................................................................................2-2<br />

2-1-2. Changing the bill guides .....................................................................2-3<br />

2-1-3. Installing the Snack Mask ...................................................................2-4<br />

2-1-4. Installing the SD Module & SD Bracket ............................................. 2-6<br />

2-2. Operation Flowchart ................................................................ 2-4<br />

2-3. Collecting bills ......................................................................... 2-5<br />

2-4. Clearing <strong>Bill</strong> Jam...................................................................... 2-6<br />

2-4-1. When a bill jammed in Transport path............................................... 2-6<br />

2-4-2. When a bill jammed in <strong>Acceptor</strong> Head .............................................. 2-6<br />

2-5. Preventive Maintenance ......................................................... 2-7<br />

2-6. Technical Support ................................................................... 2-8<br />

CHAPTER 3<br />

Disassembly Instruction<br />

3-1. How to Remove CPU/Power Supply Board ........................... 3-2<br />

3-1-1. Removing the CPU/Power Sppuly board ..........................................3-2<br />

3-2-1. Removing the timing belts..................................................................3-5<br />

3-2. Disassembly of Pusher Mechanism Assembly ..................... 3-5<br />

3-2-2. Removing the Feed motor and stacker motor .................................. 3-7<br />

3-3-1. Removing the Sensor board ..............................................................3-9<br />

3-3-2. Removing the O-rings .......................................................................3-10<br />

3-3-3. Removing the Feed Small Boards ................................................... 3-12<br />

3-4. Disassembly of Down Guide................................................. 3-13<br />

3-4-1. Removing the MAG board ................................................................ 3-13<br />

CHAPTER 4<br />

Trouble Shooting and Diagnostics<br />

4-1. Error Code & Reject Code ....................................................... 4-2<br />

4-1-1. Error Codes ......................................................................................... 4-2<br />

4-1-2. Reject Codes........................................................................................ 4-3<br />

4-2. Trouble Shooting ..................................................................... 4-4<br />

4-2-1. General Problems................................................................................4-4<br />

4-2-2. Adjustment Problems .........................................................................4-5<br />

4-2-3. Communication Problems ..................................................................4-6<br />

5

Table of Contents<br />

4-3. Diagnostics .............................................................................. 4-7<br />

4-3-1. How to enter the Test Mode ................................................................4-7<br />

4-3-2. Feed Motor Forward/Reverse Rotation Test .....................................4-7<br />

4-3-3. Stacker Test .........................................................................................4-8<br />

4-3-4. Running Test........................................................................................4-9<br />

4-3-5. Continuous Insertion Protect Lever Test ........................................ 4-10<br />

4-3-6. <strong>Acceptor</strong> Sensor Test........................................................................4-10<br />

4-3-7. Stacker Sensor Test .......................................................................... 4-11<br />

4-3-8. <strong>Bill</strong> Acceptance Test ..........................................................................4-12<br />

4-3-9. Stacker Motor Forward/Reverse Rotation Test ...............................4-13<br />

4-3-10. DIP Switch Test................................................................................4-14<br />

4-4. Sensor, board and motor location........................................ 4-15<br />

4-5. Cable Diagram........................................................................ 4-16<br />

4-5-1. DBV-301 Cable Diagram....................................................................4-16<br />

4-5-2. DBV-302 Cable Diagram....................................................................4-17<br />

CHAPTER 5<br />

Software Download and Adjustment<br />

5-1. Software Download................................................................. 5-2<br />

5-1-1. Tools Required ....................................................................................5-2<br />

5-1-2. Initial Setting ........................................................................................5-2<br />

5-1-3. Starting Dwonload Program ...............................................................5-3<br />

5-2. Adjustment .............................................................................. 5-6<br />

5-2-1. Tools Required ....................................................................................5-6<br />

5-2-2. Installing the Adjustment Program (Cab300.exe) .............................5-6<br />

5-2-3. Initial Setting ........................................................................................5-6<br />

5-2-4. Adjustment Procedure ........................................................................5-7<br />

5-3. Using Palm ............................................................................ 5-13<br />

5-3-1. Items required ................................................................................... 5-13<br />

5-3-2. Installing File Conversion Program (PdbConvEn.CAB)................. 5-13<br />

5-3-3. Initial Setting required ......................................................................5-13<br />

5-3-4. Program Overview ............................................................................ 5-14<br />

5-3-5. Download the software program from Palm ................................... 5-15<br />

5-3-6. Getting the DBV-301 unit’s setting information .............................. 5-19<br />

5-3-7. Execute the Diagnostics ...................................................................5-20<br />

5-3-8. Get the Accepting Log from DBV-30X unit ......................................5-21<br />

5-3-9. Convert the Acceptance log data into the CSV format .................. 5-24<br />

6

Table of Contents<br />

CHAPTER 6<br />

Exploded View & Parts List<br />

6-1. Entire Unit............................................................................... 6-2<br />

6-1-1. Entire Unit Exploded View ................................................................. 6-2<br />

6-1-2. Entire Unit Parts List ........................................................................... 6-3<br />

6-2. Frame and Up/Down Guide .................................................... 6-4<br />

6-2-1. Frame and Up/Down Guide Exploded View .....................................6-4<br />

6-2-2. Frame and Up/Down Guide Parts List ............................................... 6-5<br />

6-3-1. Pusher Mechanism Exploded View ..................................................6-6<br />

6-3. Pusher Mechanism Assembly .............................................. 6-6<br />

6-3-2. Pusher Mechanism Parts List ............................................................6-7<br />

6-4. Cashbox Unit.......................................................................... 6-8<br />

6-4-1. 200 note cashbox Exploded View ..................................................... 6-8<br />

6-4-2. 200 note cashbox Parts List ............................................................... 6-9<br />

6-4-1. 300 note cashbox Exploded View ................................................... 6-10<br />

6-4-2. 300 notes cashbox Parts List ........................................................... 6-11<br />

6-5-1. 1,000 note cashbox Exploded View ................................................ 6-12<br />

6-5-2. 1,000 notes cashbox Parts List ........................................................ 6-13<br />

6-5. SD Module<br />

6-5-1. SD Module Exploded View<br />

6-5-2. SD Module Parts List<br />

6-6. Snack Mask<br />

6-6-1. Snack Mask Exploded View<br />

6-6-2. Snack Mask Parts List<br />

CHAPTER 7<br />

Optional <strong>Bill</strong> Recycler Unit (RC-10)<br />

7-1. Precautions .............................................................................. 7-2<br />

7-2. RC-10 Component Names ....................................................... 7-3<br />

7-3. Specifications .......................................................................... 7-4<br />

7-3-1. Technical Specifications ..................................................................... 7-4<br />

7-3-2. Environmental Specifications ............................................................7-4<br />

7-3-4. DIP Switch Settings.............................................................................7-5<br />

7

Table of Contents<br />

7-6. Installation and Operation....................................................... 7-8<br />

7-6-1. Installing/Removing the RC-10 unit ...................................................7-8<br />

7-6-2. Installing/Removing the Cash Box ....................................................7-9<br />

7-6-3. Autoloading <strong>Bill</strong>s ...............................................................................7-10<br />

7-6-4. Stacking <strong>Bill</strong>s ..................................................................................... 7-11<br />

7-6-5. Dispensing <strong>Bill</strong> .................................................................................. 7-12<br />

7-6-6. Clearing JAM <strong>Bill</strong> ...............................................................................7-13<br />

7-7. Diagnostic Code and Wiring Diagram.................................. 7-15<br />

7-7-1. LED Diagnostic Codes ......................................................................7-15<br />

7-7-2. Wiring Diagram ..................................................................................7-16<br />

7-8. Disassembly Instruction ....................................................... 7-17<br />

7-8-1. Removing Side Cover .......................................................................7-17<br />

7-8-2. Changing Recycle Board ..................................................................7-18<br />

7-8-3. Changing PT Board/LED Board .......................................................7-19<br />

7-8-5. Changing Encoder Board ................................................................. 7-21<br />

7-9. Exploded View and Parts List ............................................... 7-22<br />

7-9-1 Exploded View ................................................................................... 7-22<br />

7-9-2. RC-10 Parts List................................................................................. 7-23<br />

8

<strong>Bill</strong> <strong>Acceptor</strong><br />

DBV-30X Service Manual<br />

Chapter 1<br />

Model Numbers<br />

& Specifications<br />

1-1. Precautions<br />

1-2. Main Features<br />

1-3. DBV-30X Naming Composition<br />

1-4. Component Names<br />

1-5. System Configuration<br />

1-6. Specifications<br />

1-7. Interface Connector and Pin Assignment<br />

1-8. DIP Switches Settings<br />

1-9. Dimensions<br />

Issue 08/2007

DBV-30X Service Manual<br />

1-1. Precautions<br />

CHAPTER<br />

1<br />

- Do not insert a torn, folded, or wet bill, as this may cause bill jam inside the unit.<br />

- Do not expose the unit to water. The unit contains several precision electronic devices<br />

which can be damaged if water or any liquid is sprayed or spilled into the unit.<br />

- Do not install the unit in a dusty environment. Dust may affect the sensor performance.<br />

- When installing the unit, be sure to turn the power OFF.<br />

- When installing the DBV-30X unit, tighten mounting nuts until snug. DO NOT overtighten.<br />

- To avoid the electrical hazards and equipment damage, be sure to use only specified<br />

voltage.<br />

1-2<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-2. Main Features<br />

The DBV-30X has the following features.<br />

1-2-1. Intelligent 3-way LED for Easy<br />

field Diagnosis<br />

DBV-30X unit has intelligent 3-way LED. It<br />

blinks depending on the error. Color of LED<br />

and the number of blinking shows the error<br />

type.<br />

1<br />

CHAPTER<br />

1-2-2. Palm Programmable<br />

Palm can be connected to DBV-30X unit to<br />

download the software program, execute the<br />

diagnostic test and get the acceptance log<br />

data. For details about connecting to Palm,<br />

refer to 5-3. Using Palm.<br />

1-2-3. Built in Auditing Functions<br />

DBV-30X unit has the following built-in<br />

functions.<br />

- Jam Rate<br />

- Acceptance Rate<br />

- Internal Diagnostics<br />

- Money Auditing<br />

1-2-4. Optional <strong>Bill</strong> Recycler (RC-10)<br />

DBV-301-SU unit can attach an optional bill<br />

recycler unit (RC-10). It is the first bill<br />

acceptor for the vending industry with built-in<br />

intelligence for recycling of notes.<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-3

DBV-30X Service Manual<br />

1-3. DBV-30X Naming Composition<br />

CHAPTER<br />

1<br />

1-3-1. Model<br />

DBV - 3 0 1 - SU<br />

(1) (2) (3) (4) (5)<br />

(1) Model Name<br />

(2) Series Name<br />

(3) CPU Board Type<br />

0: JCM Standard<br />

(4) Power supply<br />

0: DC12V<br />

1: DC24V<br />

2: AC117V<br />

(5) Stacker Type<br />

SU: Upward vertical stacking<br />

SD: Downward vertical stacking<br />

1-3-2. Type<br />

* * * - * * * * * - **<br />

(6) (7) (8) (9) (10) (11) (12)<br />

(6) Country Code *1<br />

3-digit ISO code<br />

Ex RUS - Russia<br />

(7) Cash Box Capacity<br />

2: 200 Notes Cash Box<br />

3: 300 Notes Cash Box<br />

5: 500 Notes Cash Box<br />

A: 1000 Notes Cash Box<br />

(8) Bezel Type<br />

1: JCM Standard Bezel (SU/SD)<br />

2: Snack Mask (SU/SD)<br />

3: Euro Bezel (SU)<br />

4: Euro Bezel (SD)<br />

1-4<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

(9) Guide Width<br />

1: 67 mm<br />

3: 71 mm<br />

4: 73mm<br />

(10)Cash Box Type<br />

1: Upward bill ejection box<br />

1<br />

CHAPTER<br />

(11)Recycle Type (Optional)<br />

0: without bill recycler unit<br />

1: with bill recycler unit<br />

(12)Interface Type *1<br />

D3: ID-0D3 (MDB interface)<br />

03: ID-003 (Serial interface)<br />

44: ID-044 (OEM interface)<br />

*1 For another interface, please contact JCM.<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-5

DBV-30X Service Manual<br />

1-4. Component Names<br />

CHAPTER<br />

1<br />

Cash box cover<br />

Cash box release lever<br />

RC-10<br />

Connecotr<br />

Cash box<br />

Faceplate<br />

Communication Port<br />

Indication LED<br />

AC117V<br />

Power Supply<br />

Connector<br />

(For DBV-302 Only)<br />

DIP Switch 1<br />

Interface<br />

Connector<br />

<strong>Acceptor</strong> head<br />

DIP Switch 2<br />

Condition LED<br />

<strong>Acceptor</strong> head<br />

release lever<br />

1-6<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-5. System Configuration<br />

1-5-2. DBV-300 System Configuration<br />

CHAPTER<br />

1<br />

DBV-300<br />

Interface Connector<br />

Communication Port<br />

Harness<br />

(EDP# 116490, Part# 3280-03-15)<br />

Palm (R) Tungsten C *1<br />

(EDP# G00171)<br />

Download Adapter<br />

PC<br />

(OS: Windows (R) 98 SE/2000) *2<br />

JCM Power Supply Unit<br />

(EDP# 116477, Part# VM300)<br />

Host Machine<br />

Optional Harness<br />

(EDP# 108233, Part# 3210-05-05B)<br />

*1 Palm can be connected to download a software, perform the diagnostics and<br />

collect the accepting log data.<br />

*2 PC can be connected to download software and perform an adjustment. For<br />

details about software downloading and adjustment, refer to Chapter 5.<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-7

DBV-30X Service Manual<br />

1-5-2. DBV-301 System Configuration<br />

CHAPTER<br />

1<br />

DBV-301<br />

Interface Connector<br />

Communication Port<br />

RC-10 Connector<br />

Optional <strong>Bill</strong> Recycler Unit<br />

(RC-10) *1<br />

JCM’ s<br />

OPTIPAY CC *2<br />

Palm (R) Tungsten C *3<br />

Harness<br />

(EDP# 116490, Part# 3280-03-15)<br />

Download Adapter<br />

(EDP# G00171)<br />

PC<br />

(OS: Windows (R) 98 SE/2000) *4<br />

JCM Power Supply Unit<br />

(EDP# 116480, Part# VM301)<br />

or<br />

Host Machine<br />

Optional Harness<br />

(EDP# 108233, Part# 3210-05-05B)<br />

Serial/Paluse<br />

MDB Harness<br />

(EDP# 118761, Part# 3210-05-03A)<br />

MDB<br />

*1 The optional bill recycler unit (RC-10) can be installed with only DBV-301 unit<br />

which is using MDB interface, and which is connecting with JCM’s Coin Changer<br />

(OPTIPAY CC). For details about RC-10 unit, refer to Chapter 7.<br />

*2 For details about JCM’s Coin Changer (OPTIPAY CC), please contact JCM.<br />

*3 Palm can be connected to download a software, perform the diagnostics and<br />

collect the accepting log data.<br />

*4 PC can be connected to download software and perform an adjustment. For<br />

details about software downloading and adjustment, refer to Chapter 5.<br />

1-8<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-5-3. DBV-302 System Configuration<br />

CHAPTER<br />

1<br />

DBV-302<br />

Interface Connector<br />

Communication Port<br />

Harness<br />

(EDP# 116490, Part# 3280-03-15)<br />

Palm (R) Tungsten C *1<br />

(EDP# G00171)<br />

Download Adapter<br />

PC<br />

(OS: Windows (R) 98 SE/2000) *2<br />

Host Machine<br />

Optional Harness<br />

(EDP# 108233, Part# 3210-05-05B)<br />

*1 Palm can be connected to download a software, perform the diagnostics and<br />

collect the accepting log data.<br />

*2 PC can be connected to download software and perform an adjustment. For<br />

details about software downloading and adjustment, refer to Chapter 5.<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-9

DBV-30X Service Manual<br />

1-6. Specifications<br />

CHAPTER<br />

1<br />

1-6-1. Technical Specifications<br />

<strong>Bill</strong> Accepted<br />

Insertion Direction<br />

Acceptance Rate<br />

Processing Speed<br />

Cash Box Capacity<br />

Interface<br />

Escrow<br />

LED<br />

Width (min. 65 - max. 72 mm) *1<br />

Length (min. 120 - max. 160 mm)<br />

Refer to the software Information Sheet<br />

Refer to the software Information Sheet<br />

Approx. 2 seconds (from bill insertion to credit signal output)<br />

Approx. 3 seconds (from bill insertion to bill stack completion)<br />

200 Notes Cash Box<br />

300 Notes Cash Box<br />

500 Notes Cash Box<br />

1,000 Notes Cash Box<br />

Pulse/MDB *2/Serial<br />

1 <strong>Bill</strong><br />

Condition LED (Red/Yellow/Green) (Rear)<br />

Indication LED (Green) (Front)<br />

*1 <strong>Bill</strong>s narrower than 65 mm (width) or wider than 71mm (width) will need special<br />

bill guides. Contact your JCM sales representative for details.<br />

*2 When using MDB interface, the optional bill recycler unit (RC-10) can be attached.<br />

For details about RC-10 unit, refer to Chapter 7.<br />

1-6-2. Environmental Specifications<br />

Operation Temperature *1<br />

Storage Temperature<br />

Operation Humidity *1<br />

Storage Temperature<br />

Light disturbance<br />

Installation<br />

-15 o C to 60 o C<br />

-20 o C to 60 o C<br />

+15% to 95%RH (no condensing)<br />

+15% to 95%RH (no condensing)<br />

Direct sunlight shall be avoided<br />

Indoor and Outdoor<br />

(not exposed to wind and weather)<br />

*1 Be sure to satisfy the following temperature humidity conditions.<br />

Additional Range<br />

Range of operation<br />

temperature/humidity<br />

Additional Range<br />

1-10<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-6-3. Electrical Specifications<br />

Power Supply<br />

Power Consumption<br />

1-6-4. Structural Specifications<br />

Mounting<br />

Weight<br />

Outline Dimentions<br />

DBV-300 DBV-301 DBV-302<br />

DC12V (+5%)<br />

DC24V (+5% )<br />

AC117V<br />

2.5A (Recommended) 2.5A (Recommended) AC90V to AC123V<br />

(50/60Hz)<br />

Standby: 0.3A<br />

In Operation: 0.6A<br />

(Max: 1.5A)<br />

Standby: 0.2A<br />

In Operation: 0.4A<br />

(Max: 0.9A)<br />

Holizontal Mounting<br />

Approx. 1.2kg (with 200 Note Cash Box)<br />

Refer to 1-9. Dimensions<br />

Standby: 0.07A<br />

In Operation: 0.16A<br />

(Max: 0.45A)<br />

1<br />

CHAPTER<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-11

DBV-30X Service Manual<br />

1-7. Interface Connector and Pin Assignment<br />

CHAPTER<br />

1<br />

1 2<br />

3 4<br />

5 6<br />

7 8<br />

9 10<br />

11 12<br />

13 14<br />

15 16<br />

17 18<br />

Header(Dual Light Angle Type): 702290-3007 (US MOLEX)<br />

Recommended Housing: 70066-0113 (US MOLEX)<br />

Clip (Dual Type): 70013-0018 (US MOLEX)<br />

Terminal: 70058-0204 (US MOLEX)<br />

Recommended Wire: String AWG#24 to 26<br />

1-7-1. When using ID-0D3 (MDB) Interface<br />

•DBV-301<br />

Pin No. Signal Name I/O *1 Function<br />

1 VDD1 DC24V<br />

2 VSS1 GND<br />

3 NC Not Connected<br />

4 NC Not Connected<br />

5 TXD2 OUT Photo-coupler: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong><br />

6 RXD2 IN Photo-coupler: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong><br />

7 SG2 Photo-coupler: Signal Ground<br />

8 NC Not Connected<br />

9 NC Not Connected<br />

10 NC Not Connected<br />

11 NC Not Connected<br />

12 NC Not Connected<br />

13 NC Not Connected<br />

14 NC Not Connected<br />

15 NC Not Connected<br />

16 NC Not Connected<br />

17 NC Not Connected<br />

18 NC Not Connected<br />

*1 I/O (input/output) is the term from bill acceptor’s side.<br />

1-12<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

Photo Coupler-isoration Input/Output Circuit<br />

ACCEPTOR<br />

HOST CONTROLLER<br />

CHAPTER<br />

1<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-13

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-7-2. When using ID-003 (Serial) Interface<br />

•DBV-301<br />

Pin No. Signal Name I/O *1 Function<br />

1 VDD1 DC24V *2<br />

2 VSS1 DC24V GND *2<br />

3 NC Not Connected<br />

4 NC Not Connected<br />

5 TXD2 OUT Photo-coupler: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

6 RXD2 IN Photo-coupler: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

7 SG2 Photo-coupler: Signal Ground *3<br />

8 TXD1 OUT RS-232C: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

9 RXD1 IN RS-232C: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

10 SG RS-232C/TTL: Signal Ground *3<br />

11 TXD0 OUT TTL: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

12 RXD0 IN TTL: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *3<br />

13 NC Not Connected<br />

14 NC Not Connected<br />

15 NC Not Connected<br />

16 NC Not Connected<br />

17 NC Not Connected<br />

18 NC Not Connected<br />

*1 I/O (input/output) is the term from bill acceptor’s side.<br />

*2 To avoid the electrical hazards and equipment damage, be sure to use only specified<br />

voltage.<br />

*3 The serial I/F level (Photo-coupler/RS-232C/TTL) can be selected with DIP Switch<br />

2. For details, refer to 1-8. DIP Switch Setting.<br />

•DBV-302<br />

Pin No. Signal Name I/O *1 Function<br />

1 NC Not Connected<br />

2 NC Not Connected<br />

3 NC Not Connected<br />

4 NC Not Connected<br />

5 TXD2 OUT Photo-coupler: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

6 RXD2 IN Photo-coupler: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

7 SG2 Photo-coupler: Signal Ground *2<br />

8 TXD1 OUT RS-232C: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

9 RXD1 IN RS-232C: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

10 SG RS-232C/TTL: Signal Ground *2<br />

11 TXD0 OUT TTL: Output Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

12 RXD0 IN TTL: Input Signal Line from <strong>Bill</strong> <strong>Acceptor</strong> *2<br />

13 NC Not Connected<br />

14 NC Not Connected<br />

15 NC Not Connected<br />

16 NC Not Connected<br />

17 NC Not Connected<br />

18 NC Not Connected<br />

*1 I/O (input/output) is the term from bill acceptor’s side.<br />

*2 The serial I/F level (Photo-coupler/RS-232C/TTL) can be selected with DIP Switch<br />

2. For details, refer to 1-8. DIP Switch Setting.<br />

1-14<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

Photo-coupler isolation Input/Output Circuit<br />

ACCEPTOR<br />

HOST CONTROLLER<br />

CHAPTER<br />

1<br />

RS-232C Input/Output Circuit<br />

ACCEPTOR<br />

HOST CONTROLLER<br />

TTL Input/Output Circuit<br />

ACCEPTOR<br />

HOST CONTROLLER<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-15

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-7-3. When using ID-002 (Pulse) Interface<br />

•DBV-300<br />

Pin No. Signal Name I/O *1 Function Active<br />

1 NC Not Connected<br />

2 NC Not Connected<br />

3 VDD1 DC12V<br />

4 VSS1 DC12V GND<br />

5 NC Not Connected<br />

6 NC Not Connected<br />

7 NC Not Connected<br />

8 NC Not Connected<br />

9 NC Not Connected<br />

10 SG Signal Ground<br />

11 /VEND OUT Accepted denomination Signal Lo<br />

12 NC Not Connected<br />

13 NC Not Connected<br />

14 /ENABLE IN <strong>Bill</strong> Inhibit (Hi) / Accept (Lo) Signal Lo<br />

15 NC Not Connected<br />

16 /BUSY OUT <strong>Acceptor</strong> Operating Signal Lo<br />

17 /ABN OUT <strong>Acceptor</strong> Error Signal Lo<br />

18 /FULL OUT Cash Box Full signal Lo<br />

*1 I/O (input/output) is the term from bill acceptor’s side.<br />

•DBV-301<br />

Pin No. Signal Name I/O *1 Function Active<br />

1 VDD1 DC24V<br />

2 VSS1 DC24V GND<br />

3 NC Not Connected<br />

4 NC Not Connected<br />

5 NC Not Connected<br />

6 NC Not Connected<br />

7 NC Not Connected<br />

8 NC Not Connected<br />

9 NC Not Connected<br />

10 SG Signal Ground<br />

11 /VEND OUT Accepted denomination Signal Lo<br />

12 NC Not Connected<br />

13 NC Not Connected<br />

14 /ENABLE IN <strong>Bill</strong> Inhibit (Hi) / Accept (Lo) Signal Lo<br />

15 NC Not Connected<br />

16 /BUSY OUT <strong>Acceptor</strong> Operating Signal Lo<br />

17 /ABN OUT <strong>Acceptor</strong> Error Signal Lo<br />

18 /FULL OUT Cash Box Full signal Lo<br />

*1 I/O (input/output) is the term from bill acceptor’s side.<br />

1-16<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

•Sequence Chart<br />

Accept <strong>Bill</strong><br />

DISABLE/<br />

ENABLE<br />

BUSY<br />

1<br />

CHAPTER<br />

VEND<br />

ABN<br />

FULL<br />

DISABLE<br />

DRAWING BILL<br />

and VALIDATION<br />

STACKING<br />

VEND<br />

OUTPUT<br />

STAND BY<br />

INSERT BILL<br />

STAND BY<br />

Return <strong>Bill</strong><br />

DISABLE/<br />

ENABLE<br />

BUSY<br />

VEND<br />

ABN<br />

FULL<br />

DISABLE<br />

DRAWING BILL<br />

and VALIDATION<br />

RETRUN BILL<br />

DISABLE(INHIBIT)<br />

INSERT BILL<br />

STAND BY<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-17

DBV-30X Service Manual<br />

Stack <strong>Bill</strong><br />

DISABLE/<br />

ENABLE<br />

CHAPTER<br />

1<br />

BUSY<br />

VEND<br />

ABN<br />

FULL<br />

DISABLE<br />

DRAWING BILL<br />

and VALIDATION<br />

STACKING<br />

VEND<br />

OUTPUT<br />

STACKER FULL<br />

INSERT BILL<br />

STAND BY<br />

Jam <strong>Bill</strong><br />

DISABLE/<br />

ENABLE<br />

BUSY<br />

VEND<br />

ABN<br />

FULL<br />

DISABLE<br />

DRAWING BILL<br />

and VALIDATION<br />

REJECT<br />

BILL<br />

JAMMED BILL<br />

STAND BY<br />

INSERT BILL<br />

STAND BY<br />

REMOVED BILL<br />

1-18<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-8. DIP Switch Settings<br />

DBV-30X unit have 2 DIP Switches (SW 1/SW 2). They are located on the left side of<br />

DBV-30X unit. Verify the DIP switch settings before installing the DBV-30X unit. The DIP<br />

switch settings are determined by the software. See software specifications provided separately<br />

for DIP switch settings of your software.<br />

8<br />

1<br />

CHAPTER<br />

OFF<br />

1<br />

5<br />

5<br />

4<br />

2<br />

3<br />

6<br />

7<br />

8<br />

OFF<br />

1<br />

2<br />

3<br />

4<br />

6<br />

7<br />

DIP Swich 1<br />

DIP Swich 2<br />

1-8-1. DIP Switch 1 (SW1)<br />

SW 1 sets the accepted Denomination and mode. Depending on the software, the denomination<br />

settings will differ. Refer to the software specifications.<br />

No. Function ON OFF<br />

SW1-1 Denomination 1<br />

SW1-2 Denomination 2<br />

SW1-3 Denomination 3<br />

SW1-4 Denomination 4 Inhibit<br />

Accept<br />

SW1-5 Denomination 5<br />

SW1-6 Denomination 6<br />

SW1-7 Denomination 7<br />

SW1-8 Mode Setting Test Mode *1 Normal Mode<br />

*1 For details about Test Mode, refer to 4-3. Diagnostics.<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-19

DBV-30X Service Manual<br />

1-8-2. DIP Switch 2 (SW2)<br />

DIP Switch 2 sets the Communication method. For details, refer to the software specifications.<br />

CHAPTER<br />

1<br />

ID-0D3 (MDB) interface<br />

No. Function ON OFF<br />

SW2-1 -<br />

SW2-2 -<br />

SW2-3 -<br />

SW2-4 -<br />

SW2-5 -<br />

Always OFF<br />

SW2-6 -<br />

SW2-7 -<br />

SW2-8 -<br />

ID-002 (Pulse) interface<br />

No.<br />

Function<br />

SW2-1 SW2-2 PULSE WIDTH<br />

OFF OFF 50ms/300ms<br />

ON OFF 50ms/50ms<br />

OFF ON 80ms/120ms<br />

ON ON 150ms/180ms<br />

SW2-3 SW2-4 PULSE COUNT<br />

OFF OFF 1 Pulse<br />

ON OFF 4 Pulse<br />

OFF ON 10 Pulse<br />

ON ON 20 Pulse<br />

SW2-5 Always OFF -<br />

SW2-6 Always OFF -<br />

SW2-7 Always OFF -<br />

SW2-8 Always ON -<br />

ID-003 (Serial) interface<br />

No.<br />

Function<br />

SW2-1 SW2-2 Serial I/F Level<br />

OFF<br />

OFF<br />

Photo-coupler<br />

Isoration<br />

ON OFF TTL<br />

OFF ON RS-232C<br />

ON OFF RS-232C<br />

SW2-3 Always OFF -<br />

SW2-4 Always OFF -<br />

SW2-5 Always OFF -<br />

SW2-6 Always OFF -<br />

SW2-7 Always OFF -<br />

SW2-8 Always OFF -<br />

1-20<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-9. Dimensions<br />

10.1<br />

22<br />

59.1 15.5<br />

10.5 (<strong>Bill</strong> Insertion Slot)<br />

+0.1<br />

116<br />

134.1<br />

4-5<br />

11.6<br />

59.7<br />

245.6<br />

174.3<br />

1-9-1. DBV-30X-SU with 200 Notes Cash Box<br />

88<br />

8.4<br />

2-5<br />

50.8 +0.1<br />

84 +0.1<br />

86<br />

98.2<br />

33<br />

41.5<br />

72<br />

113.5<br />

Unit : mm<br />

14.6 107<br />

4 18<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-21

DBV-30X Service Manual<br />

1-9-2. DBV-30X-SU with 300 Notes Cash Box<br />

88<br />

44<br />

2-5.4<br />

50.8<br />

CHAPTER<br />

1<br />

10.1<br />

22<br />

116 +0.1<br />

134.1<br />

86<br />

84<br />

33<br />

41.5<br />

72<br />

59.1<br />

14.6 107<br />

4 18<br />

15.5<br />

10.5 (<strong>Bill</strong> Insertion Slot)<br />

2-5.4<br />

11.6<br />

71.3<br />

249.6<br />

174.3<br />

178.3<br />

8.4<br />

98.2<br />

+0.1<br />

+0.1<br />

127<br />

Unit: mm<br />

1-22<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

1-9-3. DBV-30X-SU with 500 Notes Cash Box<br />

88 Unit: mm<br />

44<br />

2-5.4<br />

33<br />

41.5<br />

72<br />

153.5<br />

10.1<br />

14.6<br />

59.1<br />

15.5<br />

22 10.7 (<strong>Bill</strong> Insertion Slot)<br />

2-5.4<br />

116<br />

134.1<br />

107<br />

4 18<br />

11.6<br />

174.3<br />

71.3<br />

178.3<br />

249.6<br />

50.8 ±0.1<br />

84 ±0.1<br />

86<br />

8.4<br />

98.2<br />

CHAPTER<br />

1<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-23

DBV-30X Service Manual<br />

1-9-4. DBV-30X-SU with 1,000 Notes Cash Box<br />

88<br />

44<br />

86<br />

98.2<br />

CHAPTER<br />

1<br />

14.6<br />

4<br />

22<br />

59.1<br />

18<br />

134.1<br />

107<br />

15.5<br />

10.5 (<strong>Bill</strong> Insertion Slot)<br />

84 0.1<br />

33 72<br />

41.5<br />

10.1 116 0.1<br />

11.6<br />

179.3<br />

66.3 183.3<br />

249.6<br />

2-5.4<br />

50.8<br />

8.4<br />

250<br />

2-5.4<br />

0.1<br />

Unit : mm<br />

1-24<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-9-5. DBV-30X-SD with 200 Notes Cash Box<br />

98.2<br />

86<br />

84<br />

<br />

2-5.4<br />

8.4<br />

33<br />

41.5<br />

72<br />

<br />

15.5<br />

134.1<br />

+0.1<br />

116 10.1<br />

107<br />

59.1<br />

18<br />

22<br />

4<br />

14.6<br />

174.3<br />

269.1<br />

11.6<br />

71.3<br />

+0.1<br />

+0.1<br />

2-5.4<br />

90<br />

113.5<br />

Unit : mm<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-25

DBV-30X Service Manual<br />

1-9-6. DBV-30X-SD with 300 Notes Cash Box<br />

98.2<br />

86<br />

84<br />

50.8<br />

2-5.4<br />

8.4<br />

<br />

<br />

<br />

CHAPTER<br />

1<br />

<br />

2-5.4<br />

15.5<br />

134.1<br />

+0.1<br />

116 10.1<br />

107<br />

59.1<br />

18<br />

22<br />

<br />

<br />

<br />

<br />

<br />

11.6<br />

<br />

+0.1<br />

+0.1<br />

90<br />

<br />

Unit: mm<br />

1-26<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-9-7. DBV-30X-SD with 500 Notes Cash box and SD Bracket<br />

2-5.4<br />

10.7 (<strong>Bill</strong> Insertion Slot)<br />

15.5<br />

116 ±0.1 24.5<br />

61.6<br />

107 17.1<br />

18 4<br />

174.3<br />

178.3<br />

271.7<br />

14.1<br />

73.8<br />

103.2 5.9<br />

86<br />

84 ±0.1<br />

50.8 ±0.1<br />

2-5.4<br />

41.5 153.5<br />

33 72<br />

1.6<br />

Unit: mm<br />

12.6<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-27

DBV-30X Service Manual<br />

1-9-8. DBV-30X-SD with 1,000 Notes Cash Box and SD Bracket<br />

86<br />

<br />

50.8<br />

6-φ5.4<br />

33<br />

41.5<br />

72<br />

250<br />

CHAPTER<br />

1<br />

<br />

15.5<br />

<br />

107<br />

18<br />

17.1<br />

4<br />

183.3<br />

179.3<br />

107.2 3.9<br />

24.5<br />

12.6<br />

271.7<br />

14.1<br />

68.8<br />

0.1<br />

0.1<br />

1.6<br />

Unit : mm<br />

0.1<br />

61.6<br />

1-28<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

1-9-9. DBV-30X-SD with 200 Notes Cash Box and Lock Module<br />

98.2<br />

84.7<br />

84<br />

8.4<br />

2-5.4<br />

9.5 (<strong>Bill</strong> Insertion Slot)<br />

15.5<br />

107.3<br />

59.1<br />

27<br />

14.2<br />

4.4<br />

269.1<br />

11.6<br />

71.3<br />

50.8<br />

2-5.4<br />

34.5<br />

13<br />

91.1<br />

134.1<br />

116<br />

22<br />

10.1<br />

174.3<br />

132.6<br />

85<br />

90<br />

19.6<br />

24.4<br />

137.6<br />

Unit: mm<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-29

DBV-30X Service Manual<br />

1-9-10. DBV-30X-SD with 300 Notes Cash Box and Lock Module<br />

98.2<br />

8.4<br />

84.7<br />

CHAPTER<br />

1<br />

2-5.4<br />

9.5 (<strong>Bill</strong> Insertion Slot)<br />

15.5<br />

107.3<br />

59.1<br />

27<br />

14.2<br />

4.4<br />

269.1<br />

11.6<br />

71.3<br />

84 ±0.1<br />

50.8 ±0.1<br />

2-5.4<br />

34.5<br />

13<br />

91.1<br />

134.1<br />

116 ±0.1<br />

22<br />

10.1<br />

174.3<br />

178.3<br />

146.1<br />

85<br />

90<br />

19.6<br />

24.4<br />

137.6<br />

Unit: mm<br />

1-30<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

DBV-30X Service Manual<br />

CHAPTER<br />

1<br />

178.3<br />

1-9-11. DBV-30X-SD with 500 Note Cash Box, SD Bracket and Lock Module<br />

41.5 153.5<br />

33<br />

72<br />

1.6<br />

116 ±0.1<br />

2-5.4<br />

10.7 (<strong>Bill</strong> Insertion Slot) 24.5<br />

15.5<br />

61.6<br />

107<br />

17.1<br />

18 4<br />

174.3<br />

14.1<br />

12.6<br />

73.8<br />

303.1<br />

103.2 5.9<br />

86<br />

Unit: mm<br />

84 ±0.1<br />

50.8 ±0.1<br />

2-5.4<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.<br />

1-31

DBV-30X Service Manual<br />

1.6<br />

CHAPTER<br />

1<br />

183.3<br />

14.1<br />

68.8<br />

103.2<br />

±0.1<br />

±<br />

2-5.4<br />

5.9<br />

34.5<br />

13<br />

91.1<br />

269.1<br />

116 ±0.1<br />

107.3<br />

4-5.4<br />

61.6<br />

24.5<br />

14.2<br />

27 4.4<br />

271.7<br />

1-9-12. DBV-30X-SD with 1,000 Notes Cash Box, SD Bracket and Lock Module<br />

9.5 (<strong>Bill</strong> Insertion Slot)<br />

15.5<br />

12.6<br />

85<br />

90<br />

19.6<br />

24.4<br />

137.6<br />

Unit: mm<br />

1-32<br />

© 2006 Japan Cash Machine Co.Ltd. All rights reserved.

<strong>Bill</strong> <strong>Acceptor</strong><br />

DBV-30X Service Manual<br />

Chapter 2<br />

Installation<br />

& Operation<br />

2-1. Installation<br />

2-2. Operation Flowchart<br />

2-3. Collecting <strong>Bill</strong>s<br />

2-4. Clearing <strong>Bill</strong> Jam<br />

2-5. Preventive Maintenance<br />

2-6. Technical Support<br />

Issue 08/2007

DBV-30X Service Manual<br />

2-1. Installation<br />

2-1-1. Installation<br />

1) Remove the cash box and down guide.<br />

CHAPTER<br />

2<br />

2) Insert the DBV-30X unit into the panel cut<br />

out from behind the Vending machine’s<br />

door.<br />

Vending machine<br />

3) Insert the attachment screws into the<br />

DBV-30X unit’s four insertion slots.<br />

Use a screw driver to tighten each attachment<br />

screws and secure the DBV-30X<br />

unit in place.<br />

4) Install the down guide and cash box.<br />

2-2<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

2-1-2. Changing the bill guides<br />

1) Remove the cash box and down<br />

guide.<br />

SB Guide Left<br />

SB Guide Right<br />

2<br />

CHAPTER<br />

2) Remove the SB guide Left/Right in<br />

the arrow (1) and (2) direction.<br />

3) Remove the faceplate.<br />

4) Remove the FB guide in the arrow<br />

(3) direction.<br />

FB Guide<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-3

DBV-30X Service Manual<br />

2-1-3. Installing the Snack Mask<br />

1) Remove the standard faceplate.<br />

CHAPTER<br />

2<br />

2) Place the Window Spacer on the DBV-<br />

30X unit.<br />

3) Then place the FP Bracket on it.<br />

2-4<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

4) Insert the attachment screws into four<br />

(4) insertion slots are located on the<br />

rear of the DBV-30X unit. Use a<br />

screw driver to tighten each attachment<br />

screws and secure them in place.<br />

CHAPTER<br />

2<br />

5) Place the Snack Mask and insert the<br />

attachment screws into three (3) insertion<br />

slots. Use a screw driver to tighten<br />

each attachment screws and secure the<br />

snack mask in place.<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-5

DBV-30X Service Manual<br />

2-1-4. Installing the SD Module and SD<br />

Bracket<br />

1) Prepare the SD Module.<br />

- Be sure not to<br />

loose the spring.<br />

CHAPTER<br />

2<br />

2) Remove the cash box and take off the box<br />

stopper from the DBV-30X unit.<br />

Box Stopper<br />

3) Turn the DBV-30X unit upside down and<br />

slide the DBV-30X unit backward until it<br />

is locked.<br />

2-6<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

- The step 4) need to be followed only<br />

when attaching the 500 Note<br />

Cashbox and 1000 Note Cash Box.<br />

4) Attach the SD Bracket and insert the attachment<br />

screws into three (3) insertion slots. Use a<br />

screw driver to tighten each attachment screws<br />

and secure them in place.<br />

CHAPTER<br />

2<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-7

DBV-30X Service Manual<br />

2-1-5. Installing the Lock Module<br />

1) Attach the Lock Frame C to the bottom of<br />

the SD module and insert the attachment<br />

screws into two (2) insertion slots. Use a<br />

screw driver to tighten each attachement<br />

screws and secure the lock module in place.<br />

Screws<br />

Lock Frame C<br />

CHAPTER<br />

2<br />

SD Module<br />

Bottom view of the SD module<br />

Screws<br />

Top View of the SD module<br />

2) Attach the Lock Module to the SD Module<br />

and insert the attachment screws into three<br />

(3) insertion slots. Use a screw driver to<br />

tighten each attachment screws and secure<br />

the lock module in place.<br />

3) Turn the DBV-30X unit upside down and slid<br />

backward until it is locked to attach the Lock<br />

Assy .<br />

2-8<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

- Even when installing the lock<br />

module to DBV-30X-SU type<br />

unit, the SD module is also required.<br />

Follow the steps above to<br />

install the lock module to the<br />

DBV-30X-SU type unit.<br />

CHAPTER<br />

2<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-9

DBV-30X Service Manual<br />

CHAPTER<br />

2<br />

0.04<br />

2-1-6. Installing the Waterproof Kit<br />

1) Remove the base cover and the cashbox<br />

from the DBV-30X unit.<br />

2) Attach the base cover, gasket 1 and<br />

gasket 2 to the DBV-30X.<br />

3) Attach the top cover sliding until it clicks.<br />

- When installing the RC-10 unit,<br />

this step does not required.<br />

2-10<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

2-2. Operation Flowchart<br />

CHAPTER<br />

2<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-11

DBV-30X Service Manual<br />

2-3. Collecting <strong>Bill</strong>s<br />

1) Pull the cash box release<br />

lever in the arrow (1)<br />

direction.<br />

2) Lift the cash box in the<br />

arrow (2) direction and<br />

remove it.<br />

CHAPTER<br />

2<br />

3) Open the cash box cover<br />

and remove the bills.<br />

2-12<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

2-4. Clearing <strong>Bill</strong> Jam<br />

2-4-1. When a bill jammed in<br />

Transport path<br />

1) Remove the cash box (Refer to<br />

“2-3. Collecting <strong>Bill</strong>s”).<br />

2) Remove the jammed bill.<br />

CHAPTER<br />

2<br />

2-4-2. When a bill jammed in<br />

<strong>Acceptor</strong> Head<br />

1) Pull out the down guide, raising<br />

the acceptor head release lever.<br />

2) Remove the jammed bill.<br />

Down guide<br />

<strong>Acceptor</strong> head<br />

release lever<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-13

DBV-30X Service Manual<br />

2-5. Preventive Maintenance<br />

It is important to keep the bill path, rollers, and belts clean. The sensor lenses are transparent,<br />

and made of polymer material. Handle them with care. Use a soft lint-free cloth or cotton bud to<br />

wipe out dirt and stain on the surface of magnetic and optical sensors, rollers and belts. Repeat<br />

the cleaning process as needed until the transport path is free of contaminants.<br />

- Do not use alcohol or thinner for cleaning.<br />

CHAPTER<br />

2<br />

Sensor<br />

Roller<br />

Belt<br />

- JCM does not recommend cleaning cards, cleaning pads, or cleaning solutions of<br />

any kind.<br />

Up Guide and Stacker Section<br />

Down Guide<br />

Cash Box<br />

2-14<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

DBV-30X Service Manual<br />

2-6. Technical Support<br />

-Japan-<br />

Japan Cash Machine Co., Ltd. (Headquarters) Phone: +81-66-703-8406<br />

No. 3-15, Nishiwaki 2-Chome, Hirano-ku, Fax: +81-66-704-7843<br />

Osaka, 547-0035,<br />

URL: www.jcm-hq.co.jp<br />

Japan<br />

- Americas & Oceania -<br />

JCM American Corporation Phone: +1-702-651-0000<br />

925 Pilot Road, Las Vegas, NV 89119 Fax: +1-702-644-5512<br />

U.S.A.<br />

e-mail: sales@jcm-american.com<br />

URL: www.jcmamerican.com<br />

2<br />

CHAPTER<br />

- Europe, Russia, Middle East, Africa -<br />

Japan Cash Machine Germany GmbH Phone: +49-211-530-645-60<br />

Mündelheimer Weg 60 Fax: +49-211-530-645-85<br />

D-40472 Düsseldorf Germany e-mail: info@jcm-germany.com<br />

URL: www.jcm-germany.com<br />

- UK & Ireland -<br />

JCM United Kingdom Ltd. Phone: +44-(0)870-770-2863<br />

Unit B, Third Avenue, Fax: +44 (0) 190-837-7834<br />

Denbigh West Business Park<br />

e-mail: info@jcm-uk.com<br />

Bletchley, Milton Keynes,<br />

URL: www.jcm-uk.com<br />

Buckinghamshire MK1 1EJ, UK<br />

- Asia -<br />

JCM Gold (HK) Ltd. Phone: +852-2429-7187<br />

Unit 1-7, 3/F., Favor Industrial Centre Fax: +852-2929-7003<br />

2-6 Kin Hong Street, Kwai Chung, e-mail: cs@jcmgold.com.hk<br />

N.T. Hong Kong<br />

URL: www.jcmgold.com.hk<br />

© 2006 Japan Cash Machine Co., Ltd. All rights reserved.<br />

2-15

DBV-30X Service Manual<br />

NOTE<br />

CHAPTER<br />

2<br />

2-16<br />

© 2006 Japan Cash Machine Co., Ltd.. All rights reserved.

<strong>Bill</strong> <strong>Acceptor</strong><br />

DBV-30X-SU<br />

DBV-30X-SD<br />

CHAPTER 3<br />

Contents<br />

Disassembly Instruction<br />

3-1. How To Remove the CPU/Power Supply Board<br />

3-2. How To Remove the Pusher Mechanism<br />

3-3. Disassembly of Up Guide<br />

3-4. Disassembly of Down Guide<br />

Issue 03/2006<br />

Copyright © 2005 Japan Cash Machine Co.Ltd. All rights reserved.

CHAPTER 3<br />

Disassembly Instruction<br />

3-1. How to Remove CPU/Power Supply Board<br />

3-1-1. Removing the CPU/Power<br />

Sppuly board<br />

1) Pull the cash box release lever in the arrow<br />

(1) direction and remove the cash box in the<br />

arrow (2) direction.<br />

Cash Box Releace Lever<br />

Cash Box<br />

2) Pull out the down guide lifting the acceptor<br />

head release lever.<br />

<strong>Acceptor</strong> Head Release Lever<br />

3 - 2

CHAPTER 3<br />

Disassembly Instruction<br />

3) Slide upward the base cover to remove the cover.<br />

4) Remove 4 screws to remove the face plate.<br />

5) Remove 6 screws and disconnect 4 connectors.<br />

6) Remove the board assembly in the arrow direction.<br />

3 - 3

CHAPTER 3<br />

Disassembly Instruction<br />

7) Disconnect the connector from the CPU board.<br />

Release the lock and remove the flexible connector.<br />

- When disconnecting the flexible connector,<br />

be sure to handle it carefully otherwise<br />

the nail of connector breaks.<br />

8) Disconnect the connector and separate the CPU<br />

board and the Power Supply board.<br />

CPU Board<br />

Power Supply Board<br />

3 - 4

CHAPTER 3<br />

Disassembly Instruction<br />

3-2. Disassembly of Pusher Mechanism Assembly<br />

3-2-1. Removing the timing belts<br />

1) Remove the CPU board and power supply board<br />

Refer to 3-1. How to Remove Power Supply/CPU<br />

Board.<br />

2) Remove the SB guide Left/Right in the arrow (1)<br />

direction and the arrow (2) direction.<br />

SB Guide Left<br />

SB Guide Right<br />

3) Remove the front FB guide in the arrow (3)<br />

direction.<br />

FB Guide<br />

3 - 5

CHAPTER 3<br />

Disassembly Instruction<br />

4) Remove the screw and remove the pusher<br />

mechanism assembly in the arrow direction.<br />

5) Remove 2 timing belts and rollers from the<br />

pusher mechanism assembly.<br />

- When removing the timing belts<br />

from the pusher mechanism, be<br />

sure not to loose the rollers.<br />

3 - 6

CHAPTER 3<br />

Disassembly Instruction<br />

3-2-2. Removing the Feed motor and stacker<br />

motor<br />

1) Remove 2 E-rings and pull out the shaft from<br />

pusher plate.<br />

2) Slide the pusher plate in the arrow direction and<br />

remove the plate.<br />

3) Remove the E-ring and pull out the shaft from the<br />

pusher arm. Remove 2 spacers.<br />

3 - 7

CHAPTER 3<br />

Disassembly Instruction<br />

4) Lift the pusher arm and remove 5 screws<br />

and remove the motor guide.<br />

5) Remove the feed motor and stacker motor<br />

from the motor guide.<br />

3 - 8

CHAPTER 3<br />

Disassembly Instruction<br />

3-3. Disassembly of Up Guide<br />

3-3-1. Removing the Sensor board<br />

1) Remove the pusher mechanism assembly<br />

Refer to 3-2. Disassembly of Pusher<br />

Mechanism Assembly.<br />

2) Remove 2 screws and pull out the up<br />

guide.<br />

3) Pull out 2 shafts and remove 4 gears.<br />

3 - 9

CHAPTER 3<br />

Disassembly Instruction<br />

4) Remove 2 screws and remove the Sensor board.<br />

5) Release the lock and remove the flexible connector<br />

from the sensor board.<br />

- When disconnecting the flexible connector,<br />

be sure to handle it carefully otherwise<br />

the nail of connector breaks.<br />

Sensor Board<br />

3-3-2. Removing the O-rings<br />

1) Pull out 2 shafts and remove 2 gears.<br />

3 - 10

CHAPTER 3<br />

Disassembly Instruction<br />

2) Pull out the shaft and remove 2 gears.<br />

3) Pull out the shaft and remove 2 gears, 2 springs,<br />

2 bushings, 2 polly sliders and actuator.<br />

4) Remove 2 O-rings from each gears.<br />

3 - 11

CHAPTER 3<br />

Disassembly Instruction<br />

3-3-3. Removing the Feed Small Boards<br />

1) Remove the screws and both Left and Right<br />

Feed Small Board in the allow direction<br />

3 - 12

CHAPTER 3<br />

Disassembly Instruction<br />

3-4. Disassembly of Down Guide<br />

3-4-1. Removing the MAG board<br />

1) Remove the screw to remove the down guide<br />

cover in the arrow direction.<br />

2) Remove 2 screws from the MAG board.<br />

3) Disconnect the connector and remove the MAG<br />

board.<br />

MAG Board<br />

3 - 13

<strong>Bill</strong> <strong>Acceptor</strong><br />

DBV-30X-SU<br />

DBV-30X-SD<br />

CHAPTER 4<br />

Contents<br />

Trouble Shooting and Diagnostics<br />

4-1. Error Codes and Reject Codes<br />

4-2. Trouble Shooting<br />

4-3. Diagnostics<br />

4-4. Sensor, Board and Motor Locations<br />

4-5. Cable Diagrams<br />

Issue 03/2006<br />

Copyright © 2005 Japan Cash Machine Co.Ltd. All rights reserved.

CHAPTER 4 Trouble Shooting and Diagnostics<br />

4-1. Error Code & Reject Code<br />

This section explains the error code and the reject code. The following tables lists the Condition LED's color, the<br />

number of blinking and their meanings. When an error and rejection occurs, check the Condition LED’s color and<br />

the number of blinking and detect the cause.<br />

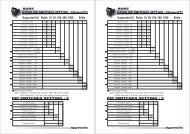

4-1-1. Error Codes<br />

Condition<br />

LED<br />

Discription<br />

R Y G<br />

Stacker Full<br />

1<br />

2 Stacker JAM<br />

<strong>Acceptor</strong> JAM<br />

3<br />

(When recycler working)<br />

4 <strong>Acceptor</strong> JAM<br />

5 Feed Motor Speed Error<br />

6 Feed Motor Lock<br />

Instruction waiting from host when the bill<br />

7<br />

is escrow<br />

Solution<br />

Cash box is full. Collect the bill. Refer to<br />

2-3. Collect the bill.<br />

Remove the Jam bill. Refer to 2-4.<br />

Clearing <strong>Bill</strong> Jam.<br />

Perform the Diagnostic. Refer to 4-3.<br />

Diagnostic.<br />

8 Reserved<br />

Remove the Jam bill. Refer to 2-4.<br />

9 Continuous Insertion Protect Lever JAM<br />

Clearing <strong>Bill</strong> Jam.<br />

10 Box is not set.<br />

11 Box Sensor Error<br />

Set the cash box properly. When the<br />

error is not reset, perform the Diagnostic.<br />

Refer to 4-3. Diagnostic.<br />

12 Cheating<br />

Cheating was occurred. When reset the<br />

error, remove/install the cash box.<br />

13 Down Guide is not set. Set the Down Guide properly.<br />

14<br />

Reserved<br />

EEPROM Read Error is occurred. When<br />

reset the error, remove/install the cash<br />

15 EEPROM Read Error<br />

box. When the error is not reset, adjust<br />

the DBV-30X unit. Refer to 5-2.<br />

Adjustment.<br />

4 - 2

CHAPTER 4 Trouble Shooting and Diagnostics<br />

4-1-2. Reject Codes<br />

Condition<br />

LED<br />

Description<br />

R Y G<br />

1 Insertion Error<br />

2 Magnetic Error<br />

3 Paper detected inside acceptor at standby<br />

4 Adjustment/Magnification Error<br />

5 Reject by Feed Error<br />

6 Denomination Select Error<br />

7 Photo Pattern Error (1)<br />

8 Photo Level Error<br />

9 Inhibited <strong>Bill</strong><br />

10 Return direction from host machine<br />

11 Foreign substances detection of the exit sensor<br />

12 Escrow Position Error<br />

13 <strong>Bill</strong> Length Error<br />

14 Photo Pattern Error (2)<br />

15 Incompatible <strong>Bill</strong> Error<br />

4 - 3

CHAPTER 4 Trouble Shooting and Diagnostics<br />

4-2. Trouble Shooting<br />

4-2-1. General Problems<br />

Symptoms/Error Messages Possible Causes Corrective Action<br />

<strong>Bill</strong> <strong>Acceptor</strong> is not working<br />

(does not take any bills).<br />

<strong>Bill</strong> is jamming often.<br />

Low acceptance rates.<br />

No external power is applied to the<br />

bill acceptor<br />

Wrong or inappropriate connections<br />

Software is not downloaded.<br />

Sensor/MAG/CPU/Power Supply<br />

board failure.<br />

Entrance Sensor is not working or<br />

foreign object in the entrance.<br />

Drive belts are dirty or damaged.<br />

Pressure roller spring is loose or<br />

missing.<br />

Foreign object in the transport path<br />

and inside the Cash Box.<br />

<strong>Bill</strong> guide is not inappropriate.<br />

<strong>Bill</strong> is wider than 72 mm or narrower<br />

than 65mm<br />

(out of DBV-30X specifications).<br />

Dirt and stain on the rollers, belts and<br />

lenses.<br />

Sensors need to be clean and adjust.<br />

The unit has been disassembled and<br />

the Adjustment is not done after it is<br />

reassembled.<br />

Using wrong software or old version<br />

software.<br />

<strong>Bill</strong>s are not to be accepted in this<br />

software.<br />

Verify that the appropriate input voltage and<br />

ground are connected to appropriate pins on<br />

the main connector.<br />

Check the connections of all harnesses and<br />

connectors. Check for any bent, missing or<br />

damaged pins in the connectors. Check the<br />

specified voltage is used in appropriate pin.<br />

Download the correct software. Refer to<br />

chapter 5 for download instructions.<br />

Refer to 5-2. Diagnostics and conduct Running<br />

Test. If the test result is NG, replace<br />

Sensor/MAG/CPU/Power Supply board. Make<br />

sure to adjust the sensors after Sensor<br />

/MAG/CPU/Power Supply board is replaced.<br />

Remove the foreign object and clean the<br />

sensor. Perform the acceptor sensor test. Refer<br />

to 4-3-6. <strong>Acceptor</strong> Sensor Test. If the test result<br />

is NG, replace CPU board. Refer to 3-1. How<br />

to Remove the Circuit Board.<br />

Clean the drive belts and the pressure rollers.<br />

Replace as necessary. Refer to 2-5.<br />

Preventive Maintenance.<br />

Check the pressure roller springs with finger<br />

and replace as necessary.<br />

Clean the transport path and the cash box to<br />

remove the foreign object. Refer to 2-5.<br />

Preventive Maintenance.<br />

Seat the transport unit all the way back so that<br />

the latches of transport unit release levers are<br />

locked in the frame.<br />

Use only bills within DBV-30X specifications.<br />

Clean the transport path. Refer to 2-5.<br />

Preventive Maintenance.<br />

Clean the transport path. Refer to 2-5.<br />

Preventive Maintenance.<br />

Follow the instructions on 5-1. Adjustment to<br />

adjust the sensors.<br />

Make sure to adjust the sensors after reassemble<br />

the DBV-30X.<br />

Make sure if the programmed software is the<br />

latest version and it supports the bills you wish to<br />

be accepted.<br />

Check the specifications, and make sure the bills<br />

are to be accepted in the software (check<br />

denomination/issuing year).<br />

4 - 4

CHAPTER 4 Trouble Shooting and Diagnostics<br />

Symptoms/Error Messages Possible Causes Corrective Action<br />

Wrong software (different currency).<br />

Download correct software. Refer to 5-1.<br />

Software Download.<br />

Wrong DIP switch settings.<br />

Enable the denominations by setting DIP<br />

switches OFF<br />

<strong>Bill</strong> acceptance is inhibited by the<br />

All bills are rejected.<br />

command from host controller.<br />

Enable the bill acceptance by the command.<br />

Sensor/MAG/CPU board failure.<br />

Change the Sensor/MAG/CPU board. Refer to<br />

3-5. How to remove Circuit Boards.<br />

Refer to 2-5. Preventive Maintenace to clean<br />

Sensors need to be clean and<br />

the sensors. Follow the instructions on 5-2.<br />

adjusted.<br />

Adjustment to adjust the DBV-30X.<br />

The motor rotates several time and<br />

stops.<br />

Can not enter the TEST mode.<br />

CPU board failure.<br />

Wrong DIP switch settings.<br />

Dip switch failure.<br />

CPU Board failure.<br />

Refer to the 3-1. How to Remove the Circuit<br />

Board.<br />

Set the switch SW1-8 ON, and then supply<br />

power to the DBV-30X unit.<br />

Refer to the 4-2. Diagnostics and conduct DIP<br />

Switch TEST to check if the DIP switch has a<br />

failure.<br />

Change the CPU board. Refer to 3-5. How to<br />

Remove Circuit Boards.<br />

4-2-2. Adjustment Problems<br />

Symptoms/Error Messages Possible Causes Corrective Action<br />

Our Adjustment program supports only Windows<br />

Can not start the Cab300.exe<br />

OS is not applicable.<br />

98 Second Edition/2000.<br />

program by double-clicking.<br />

The program files are corrupted. Ask JCM for the correct programs.<br />

Check the connections of PC and DBV-30X<br />

Wrong or inappropriate connections connectors. Check for any bent, missing or<br />

damaged pins in the connectors.<br />

Set the DBV-30X unit's DIP switches SW1-1 to<br />

DIP switch setting of DBV-301 is not<br />

SW1-7 OFF and SW1-8 ON, and turn on the<br />

correct.<br />

power of VM30X.<br />

Communication Error.<br />

Refer to the 4-2. Diagnostics and conduct DIP<br />

DIP switch failure.<br />

Switch Test.<br />

CPU board failure.<br />

Change the CPU board. Refer to 3-1. How to<br />

Remove Circuit Boards.<br />

Power is not supplied.<br />

Change the Power Supply board. Refer to 3-1.<br />

How to Remove Circuit Boards.<br />

Harness failure IFU-002 is broken. Please exchange it.<br />

Adjustment Error.<br />

Wrong reference paper.<br />

Follow the instruction on the Adj300.exe<br />

program and use the correct reference paper.<br />

Sensor/MAG/CPU boards failure.<br />

Change the Sensor/MAG/CPU board. Refer to<br />

3-5. How to Remove Circuit Boards.<br />

4 - 5

CHAPTER 4 Trouble Shooting and Diagnostics<br />

4-2-3. Communication Problems<br />

Symptoms/Error Messages Possible Causes Corrective Action<br />

DIP switch settings are wrong. Set all DIP switches OFF.<br />

Connectors are disconnected or<br />

loosely connected.<br />

Firmly connect all the connectors.<br />

Check for any bent, missing or damaged pins in<br />

Damaged connector pins.<br />

Can not communicate with host.<br />

the connectors.<br />

CPU/Power Supply board is<br />

corrupted.<br />

Replace CPU/Power Supply board. Refer to<br />

Chapter 3 Disassembly Instructions.<br />

Wrong interface.<br />

Check if the interface is the same for the host<br />

machine and the bill acceptor.<br />

4 - 6

CHAPTER 4 Trouble Shooting and Diagnostics<br />

4-3. Diagnostics<br />

DBV-30X is equipped with diagnostic feature to aid in repair and maintenance. This section describes<br />

the test procedure of each function using DIP switch to identify the cause of failure<br />

condition. To identify the cause of failure condition, DBV-30X need to be entered in the Test mode.<br />

4-3-1. How to enter the Test Mode<br />

1) Set SW1-8 ON and SW1-1 to SW1-7 OFF then supply the DBV-301 power ON.<br />

2) The Indication LED located on the faceplate is blinking and the Condition LED (green, yellow and<br />

red) located on the rear of the unit lights. This indicates the unit is in the Test mode.<br />

3) Set the DIP switches SW1-1 to SW1-7 depending on the test you wish to execute.<br />

(See 4-2-2 to 4-2-10)<br />

4) Set the SW1-8 OFF to start the test. When the test starts, Indication LEDs turns OFF and all green,<br />

yellow and red Condition LEDs turns OFF. After few seconds, the Condition LEDs turn ON/OFF<br />