Manufacturing Machinery World May 2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MAY <strong>2017</strong><br />

www.<strong>Machinery</strong>.world<br />

Join us on<br />

The No.1 International<br />

Machine Tool Journal<br />

@<strong>Machinery</strong>W<br />

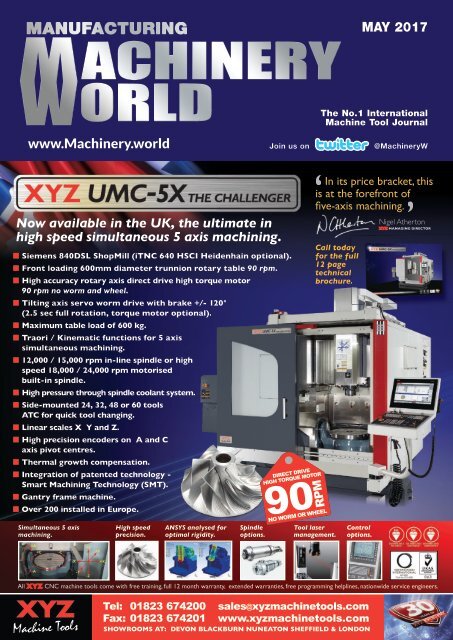

Now available in the UK, the ultimate in<br />

high speed simultaneous 5 axis machining.<br />

n Siemens 840DSL ShopMill (iTNC 640 HSCI Heidenhain optional).<br />

n Front loading 600mm diameter trunnion rotary table 90 rpm.<br />

n High accuracy rotary axis direct drive high torque motor<br />

90 rpm no worm and wheel.<br />

n Tilting axis servo worm drive with brake +/- 120°<br />

(2.5 sec full rotation, torque motor optional).<br />

n Maximum table load of 600 kg.<br />

n Traori / Kinematic functions for 5 axis<br />

simultaneous machining.<br />

n 12,000 / 15,000 rpm in-line spindle or high<br />

speed 18,000 / 24,000 rpm motorised<br />

built-in spindle.<br />

n High pressure through spindle coolant system.<br />

n Side-mounted 24, 32, 48 or 60 tools<br />

ATC for quick tool changing.<br />

n Linear scales X Y and Z.<br />

n High precision encoders on A and C<br />

axis pivot centres.<br />

n Thermal growth compensation.<br />

n Integration of patented technology -<br />

Smart Machining Technology (SMT).<br />

n Gantry frame machine.<br />

n Over 200 installed in Europe.<br />

Simultaneous 5 axis<br />

machining.<br />

High speed<br />

precision.<br />

ANSYS analysed for<br />

optimal rigidity.<br />

Spindle<br />

options.<br />

DIRECT DRIVE<br />

HIGH TORQUE MOTOR<br />

RPM<br />

90<br />

NO WORM OR WHEEL<br />

‘<br />

In its price bracket, this<br />

is at the forefront of<br />

ve-axis machining.<br />

Call today<br />

for the full<br />

12 page<br />

technical<br />

brochure.<br />

Tool laser<br />

management.<br />

Control<br />

options.<br />

‘<br />

Nigel Atherton<br />

XYZ MANAGING DIRECTOR<br />

All XYZ CNC machine tools come with free training, full 12 month warranty, extended warranties, free programming helplines, nationwide service engineers.<br />

Tel: 01823 674200 sales@xyzmachinetools.com<br />

Fax: 01823 674201 www.xyzmachinetools.com<br />

SHOWROOMS AT: DEVON BLACKBURN NUNEATON SHEFFIELD & LONDON

CONTENTS<br />

MAY ISSUE<br />

MANAGING DIRECTOR:<br />

Carole Titmuss<br />

NEWS EDITOR:<br />

Pat Fairfax<br />

FEATURES EDITOR:<br />

Danielle Titmuss MSc<br />

SALES:<br />

Tracy Chamberlain<br />

PRODUCTION:<br />

Ian Purves, James Kennett,<br />

Jonathan Milburn<br />

SUBSCRIPTIONS:<br />

Wendy Burnett<br />

PUBLISHERS:<br />

Carole Titmuss Tony Prior.<br />

Front Cover:<br />

XYZ Machine Tools<br />

AUCTIONS 41<br />

FEATURES<br />

EDM 14-15<br />

SUBCON / Advanced <strong>Manufacturing</strong> Show. 22-25<br />

Saws and blades to fit<br />

your budget and<br />

application<br />

Quick<br />

<br />

NEW PRODUCTS 36-37<br />

SERVICE DIRECTORY 38-39<br />

Our comprehensive guide to Product & Service<br />

Providers to the manufacturing industry.<br />

NEXT MONTH EXHIBITION ISSUE<br />

SUBCON / Advanced <strong>Manufacturing</strong> Show.<br />

6-8 June, NEC.<br />

Paris Airshow 19-25 June.<br />

NEXT MONTH’S FEATURES<br />

Robotics, chucks, Clamps & Work Holding equipment.<br />

Faster<br />

<br />

This journal includes editorial photographs provided and paid for by suppliers.<br />

<strong>Machinery</strong> <strong>World</strong> is available on subscription annual rate:<br />

UK £40, Europe £64, Overseas £88<br />

Single Copies £3.50 UK £6 Overseas<br />

Published by: SHEEN PUBLISHING LTD<br />

50 QUEENS ROAD, BUCKHURST HILL, ESSEX IG9 5DD<br />

TELEPHONE: 020 8504 5912, 020 8504 1661<br />

International: +44 20 8504 1661<br />

FACSIMILE: 020 8505 4336<br />

International: +44 20 8505 4336<br />

Web: www.machinery.world Email: info@machinery.world<br />

Twitter: @<strong>Machinery</strong>W<br />

ISSN 1745-5898<br />

MACHINERY WORLD is published monthly and is circulated to senior personnel who<br />

influence the buying and selling of new and used metal working machinery worldwide.<br />

Fastest<br />

<br />

www.accurate-cutting.co.uk<br />

©Sheen Publishing Ltd. All rights reserved. No part of this<br />

publication may be reproduced or transmitted in any form or<br />

by any means, including photocopying and recording, without<br />

the written permission of the publishers. Such written<br />

permission must also be obtained before any part of this<br />

publication is stored in a retrieval system of any nature.<br />

w w w . m a c h i n e r y. w o r l d<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong> 3

NEWS NEWS NEWS<br />

neW GrinDinG<br />

macHine<br />

installeD in tHe<br />

master<br />

sHoWroom<br />

Master Abrasives has been busy setting up a<br />

new showroom at its Daventry location for<br />

demonstrating precision grinding products<br />

including abrasives, dressers, and<br />

Micromatic grinding machines. Following<br />

the recent visit of an installation engineer<br />

from Micromatic Grinding Technologies, the<br />

eco 200 universal hydraulic cylindrical<br />

grinding machine is now installed and ready<br />

for demonstration in the Master showroom.<br />

Martin Stevens, Technical Sales<br />

Representative for grinding machines and<br />

precision products, says “Having the eco 200<br />

installed at our showroom facility will be a<br />

great aid in showing customers the<br />

capabilities of Micromatic machines.<br />

Demonstrations of the eco 200 can be<br />

arranged on request and we already have<br />

many interested customers who have<br />

scheduled their visit to see the machine.”<br />

The high-performance brand of<br />

MASTER® grinding wheels and dressers will<br />

be available to use in demonstration of the<br />

eco 200 to provide efficient grinding and<br />

surface finishing. The showroom machine is<br />

set up with a coolant application nozzle<br />

system by Cool-Grind Technologies,<br />

providing accurate coolant flow and pressure<br />

to the process. This gives visitors the<br />

opportunity to see Grind-Loc nozzles in<br />

action and understand how they can help to<br />

achieve optimum performance from<br />

grinding processes.<br />

Q8Oils has worked with Master<br />

Abrasives to supply the suitable oils and<br />

cutting fluid for the eco 200 U demonstration<br />

machine. The team of technical experts has<br />

provided products to improve the<br />

operational efficiency and optimise the<br />

production process.<br />

tel: 01327 703813<br />

email: sales@master-abrasives.co.uk<br />

Web: www.master-abrasives.co.uk<br />

mta <strong>2017</strong> propels a DiGitaliseD<br />

manuFacturinG sector<br />

In light of manufacturing’s shift towards a<br />

new era of digitalisation, technologies and<br />

solutions for Industry 4.0 such as 3D<br />

printing, automation, Industrial Internet of<br />

Things (IIoT) and robotics are increasingly<br />

being sought after.<br />

Showcases that brought these<br />

technologies to light were well-received at<br />

MTA<strong>2017</strong>, Asia’s premier manufacturing<br />

technology industry event, which concluded<br />

last Friday at the Singapore Expo. The 300-<br />

exhibitor event provided a useful platform<br />

for companies to conduct business, and tap<br />

into the talent and experience from the<br />

industry community. Through participating<br />

in MTA<strong>2017</strong>, companies will emerge more<br />

agile in adjusting to shifting economic and<br />

industry landscapes, and better positioned<br />

for business growth in a digitalised future.<br />

MTA<strong>2017</strong> underlined how Industry 4.0<br />

technologies can be implemented. At the<br />

Smart <strong>Manufacturing</strong> Pavilion and Smart<br />

<strong>Manufacturing</strong> Asia conference, exhibitors<br />

and speakers imparted deep insights and<br />

conducted live demonstrations, which<br />

enabled attendees to visualise how<br />

digitalisation will enhance their processes,<br />

operations and services.<br />

The Smart <strong>Manufacturing</strong> Asia <strong>2017</strong><br />

conference gathered more than 30 industry<br />

Seco has extended its range of Duratomic<br />

inserts for steel turning applications to<br />

include a new grade - TP3501.<br />

The grade is aimed at manufacturers<br />

machining (turning) steel and stainless steel<br />

components, and is especially suited to<br />

heavy-duty operations involving interrupted<br />

cuts and where less stable machine tools are<br />

being used. The grade is also ideal for<br />

machining awkward- and asymmetricshaped<br />

parts where weak and/or relatively<br />

‘unstable’ work-holding is being used, as<br />

well as for components with small internal<br />

features.<br />

TP3501 joins the previously launched<br />

TP2501, TP1501 and TP0501 grades and<br />

completes Seco’s steel turning Duratomic<br />

grade line-up.<br />

TP3501 inserts feature Seco’s innovative<br />

Duratomic Al2o3 coating technology which,<br />

by manipulating it at an atomic level,<br />

delivers improved mechanical and thermal<br />

performance and a better balance between<br />

insert toughness and hardness.<br />

The new TP inserts, which are chrome in<br />

colour, incorporate Seco’s Used Edge<br />

Detection functionality that allows users to<br />

thought leaders and experts who provided<br />

deep insights and topical case studies on<br />

Industry 4.0, IIoT, augmented reality and<br />

robotics.<br />

3D Printing was a big focus at MTA<strong>2017</strong>.<br />

From show floor exhibits to technology tours<br />

and interactive seminars, visitors saw a wide<br />

array of industrial applications and<br />

innovative concepts across industries from<br />

aerospace to medical technology, displayed<br />

by exhibitors BeAM, Chemtron, Creatz3D,<br />

EOS, Eye-2-Eye Communications, Nanyang<br />

Polytechnic, Renishaw, SLM Solutions,<br />

TRUMPF and UCT Additive <strong>Manufacturing</strong><br />

Center.<br />

The show floor buzzed with excitement as<br />

ABB, Epson and Nachi held regular<br />

demonstrations of their robots.<br />

MTA<strong>2017</strong> drew more than 10,000<br />

attendees from 43 countries/regions. This<br />

includes 13 group delegations from<br />

Malaysia, Philippines and Singapore,<br />

comprising of executives from Hewlett<br />

Packard Enterprise, the Penang Foundry &<br />

Engineering Industries Association, the<br />

Philippine Die & Mould Association, Pratt &<br />

Whitney, Small & Medium Enterprises<br />

Association Malaysia, ST Logistics and<br />

Singapore Aerospace <strong>Manufacturing</strong>.<br />

email: mta@sesallworld.com<br />

Duratomic line-up completeD WitH<br />

introDuction oF tp3501 GraDe<br />

easily identify if an insert edge has been used<br />

(i.e. through being able to see wear scars)<br />

and, as a consequence, ensures that unused<br />

inserts are not discarded before they need to<br />

be.<br />

The TP3501 range is comprehensive. It<br />

includes just under 400 different insert types<br />

with a wide range of geometries that includes<br />

the proven, well-established and ultra-strong<br />

M6 (double-sided, negative) chip breaker.<br />

tel: 01789 7642207<br />

email: mike.fleming@secotools.com<br />

Web: www.secotools.com/gb<br />

4 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

EXCELLENCE THROUGH INNOVATION<br />

CNC Plasma Profiling <strong>Machinery</strong><br />

Why buy a<br />

Swift-Cut<br />

CNC Plasma<br />

Cutting<br />

Machine<br />

British designed, engineered and technically supported.<br />

Reduces cost and removes reliance on outsourced profiling.<br />

Eliminates timescales waiting for outsourced parts<br />

Ability to prototype and guarantee quality.<br />

Provides in-house research and development opportunities.<br />

Increase in turnover and opportunity to diversify.<br />

Excellent support and customer service.<br />

www.swift-cut.com - sales@swift-cut.co.uk - +44 (0)1543 473300

CNC<br />

Your search for the right machine is top of our priority<br />

Always Excellent Quality, Value and Service<br />

Looking for solutions to the challenges you face in your everyday working<br />

environment? Or require further training to excel in your career? Your problems<br />

are our priority! With a wide range of small & large industrial products - Excel<br />

Machine Tools strives to provide your requirements with quality machinery &<br />

accessories at a competitive price.<br />

MAIN CATALOGUE 2015 / 2016<br />

Superior Quality Professional Machine Tools<br />

Excel operates from a purpose built factory located in Coventry; the engineering<br />

heartland of the UK. It boasts a fully equipped assembly workshop staed by<br />

skilled engineers and technicians. A part of the site is set aside as a working<br />

machine demonstration area. This has proved very popular with the customers<br />

who want the opportunity to test which machine best suits their application. By<br />

far and away the largest area of the factory is the main warehouse. This contains<br />

an impressive wide range of stock that includes standard and special machines<br />

ready for immediately delivery. CNC/manual lathes, CNC/manual Mills, Drilling<br />

machines, Grinders, Saws, Shearing machines, Ring Rollers, Hydraulic Plate<br />

Bending machines, Accessories and lots more. Many are awaiting modication<br />

to the customer’s specication. This extensive stock enables Excel to deliver a<br />

level of customer service that is the envy of our competitors. It enables Excel to<br />

respond quickly to each and every enquiry, irrespective of its size of complexity.<br />

As we source products internationally we are able to provide up-to-the-minute,<br />

impartial advice & guidance on the best & best value for money solutions for<br />

our customers. Our commitment to support our customers extends to technical<br />

advice at the end of a phone our history in the industry has led to building very<br />

good relationships with one of the widest range of manufacturers in the world.<br />

Combined with our commitment to investment & warehousing, we are able to<br />

oer speedy delivery on all lines. We also oer same day collection or overnight<br />

delivery on spare parts & accessories from our comprehensive stores. We hold<br />

the international quality standard ISO 9001, this is possible only because we<br />

employ fully qualied technicians & engineers working to high standards, which<br />

are in-turn driven by stringent pre-delivery checks & testing. Excel machines and<br />

parts are covered by a full twelve months on-site parts and labour warranty for<br />

the UK and full 12 months parts warranty for overseas. After the initial twelve<br />

month period, Excel oers a continuing warranty service, which can include parts<br />

and labour, at highly competitive rates. We maintain a comprehensive stock of<br />

replacement parts for each of our machines. Excel also stocks a large range of<br />

accessories to t Excel machines.<br />

CNC MACHINES | GRINDERS | LATHES | SHEARS<br />

DRILLS | MILLS | GUILLOTINES | SAWS | SHAPERS<br />

PLATE BENDING ROLLS | PRESS BRAKES | LOTS MORE!<br />

WWW.EXCELMACHINETOOLS.CO.UK<br />

We also specialise in the supply and commissioning of teaching workshops for<br />

schools, colleges, polytechnics, universities and industry training establishments.<br />

The extensive range of Excel products t exceptionally well to every teaching<br />

situation. The range of basic, low cost, manual machines provides excellent<br />

initial training. Cost eective CNC systems deliver you advanced instruction<br />

for students preparing to enter the workplace. (Training is available on-site on<br />

request).You receive training in programming as part of the supply of every new<br />

machine. Additional training or programming support is available to you at any<br />

time; after commissioning or when you take on new sta. Occasional software<br />

support is given free. Structured training and programming design is charged at<br />

very reasonable rates.<br />

Having satised the requirements of schools, colleges, engineering & general<br />

workshops with sourcing, supplying, installing & commissioning, along with<br />

service back-up and continuous support . Why not view our product Catalogue<br />

on our website. Or pop over to our showroom and we will ensure you leave with<br />

concrete answers & solutions to all your issues & concerns. With a satised<br />

repeat consumer base, our existing customers save time & money with quality<br />

long life products.<br />

We have extended our range of high quality machines, these now comprise of<br />

additional Metalworking/CNC machines, a new range of Woodworking products,<br />

Lifting/Workshop Technology and Welding Equipment.If you would like to view<br />

our new range of catalogues that feature these machines please contact us for a<br />

printed copy or visit our new website www.excelmachinetools.co.uk<br />

NEW<br />

RANGE<br />

Working in<br />

partnership with<br />

‘Always Excel’<br />

‘Always Excel’<br />

Magnetic drilling machines<br />

Metal working machines<br />

Belt grinding machines<br />

Surface grinding machines<br />

Sheet metal shears<br />

Notching machines<br />

Hole punchers<br />

Ring bending machines<br />

Round bending machines<br />

Swivel bending machines<br />

Folding presses<br />

Shop presses<br />

Circular metal saws<br />

Roller conveyors<br />

Metal band saws<br />

Accessories<br />

‘Always Excel’ Excel’<br />

Working in Partnership with<br />

‘Always ‘Always Excel’<br />

CNC milling machines CNC metal working machines<br />

CNC lathes<br />

The OPTIMUM in quality, price-performance and service<br />

Automation<br />

CNC software<br />

Accessories<br />

mill ®<br />

turn ®<br />

Working in Partnership with<br />

‘Always ‘Always Excel’ Excel’<br />

Bench drilling machines<br />

Metal working machines<br />

Upright drilling machines<br />

The OPTIMUM in quality, price-performance and service<br />

Gear drilling machines<br />

Lathes<br />

Milling machines<br />

Metal band saws<br />

Metal circular saws<br />

Grinding machines<br />

Polishing machines<br />

Drill bit grinder<br />

Sheet metal processing<br />

Arbor presses<br />

Measuring tools<br />

CNC add-on kit´s<br />

Working in partnership with<br />

‘Always Excel’<br />

Excel’<br />

Scissor-type lifting tables Lifting and workshop technology<br />

Pallet trucks<br />

Pallet stackers<br />

Handcarts<br />

Transport rollers and chassis<br />

Trolley jacks<br />

Body straightening kits<br />

Lifting gear<br />

Load handling equipment<br />

Chain hoists<br />

Rope winches<br />

Machine jacks<br />

Workshop presses<br />

Working in partnership with<br />

‘Always Excel’<br />

‘Always Excel’<br />

Belt saws<br />

Wood working machines<br />

Wet-dry grinder<br />

for do-it-yourselfers and craftsmen<br />

Belt and disk sander<br />

Edge sanding machines<br />

Cylinder sanding machines<br />

Circular table & Scroll saws<br />

Surface planing machines<br />

Wood turning lathes<br />

Suction plants<br />

Material stand<br />

Joiner’s benches<br />

Long hole drills<br />

Edge banders<br />

Power grinders<br />

Workshop equipment<br />

Accessories<br />

CNC main catalogue 2015/16<br />

Main catalogue 2015/16

UK PARTNERS FOR GERMAN STURMER GROUP<br />

WIDE RANGE<br />

OF SAWS<br />

‘ALWAYS EXCEL’<br />

‘The Price, Service &<br />

Deomonstration Inuenced<br />

Graham Morris to buy from Excel’<br />

CALL US ON 024 7636 5255

NEWS NEWS NEWS<br />

ToTal Turbomachinery SoluTion<br />

wiTh hypermill ®<br />

SoftInWay Inc. and OPEN MIND<br />

Technologies AG announce a cooperation<br />

agreement to provide a complete solution for<br />

the design, development and manufacturing<br />

of gas turbine components and other types of<br />

turbo machinery. Both companies are known<br />

for their best-in-class software platforms that<br />

provide component developers the needed<br />

productivity tools to accelerate the product<br />

development and production process while<br />

maintaining a high level of accuracy.<br />

The AxSTREAM® Software Platform<br />

provides an integrated and streamlined<br />

approach to turbo machinery design. The<br />

software consists of a number of different<br />

modules to perform preliminary design,<br />

meanline and streamline analysis, CFD and<br />

FEA, blade profiling, and rotor dynamics,<br />

bearings analysis, and rotor design for<br />

compressors, pumps and turbines. These<br />

tools are used to produce optimal<br />

components, considering speed, power,<br />

range, and life. The interactive and userfriendly<br />

design process enables these<br />

conditions to be achieved efficiently and<br />

reliably.<br />

hyperMILL® is a modular complete CAM<br />

solution for 2.5D, 3D, 5-axis, HSC/HPC, and<br />

mill-turning processes as well as its special<br />

applications and highly efficient automation<br />

solutions. The CAM software provides<br />

technology-leading geometry analysis and<br />

tool path calculations. There are specialized<br />

routines designed for efficient programming<br />

and machining of these components on 5-<br />

axis milling or mill-turn machines. The<br />

multi-blade and single-blade turbo<br />

machinery solutions are embedded within<br />

hyperMILL® that is applied to more broadbased<br />

milling, drilling and turning<br />

applications, allowing an all-in-one CAM<br />

system for turbo machinery developers.<br />

Robust CNC postprocessors are also<br />

provided to assure strong communication to<br />

machine tool controllers.<br />

This partnership between SoftInWay and<br />

OPEN MIND brings product, services, sales<br />

and technical teams together for a complete<br />

software solution. Customers can work with<br />

each company to obtain tools, training and<br />

services from these industry experts. Both<br />

companies are well represented with direct<br />

employees and authorized resellers in<br />

America, Europe and Asia and look forward<br />

to collaborating together to contribute<br />

towards the advancement of the turbo<br />

machinery industry.<br />

email: adrian.smith@openmind-tech.com<br />

web: www.openmind-tech.com<br />

amada end The financial year<br />

on a high<br />

Over 180 people from companies across the<br />

UK and Ireland have attended AMADA<br />

UK’s three day exhibition at their Technical<br />

Centre in Kidderminster.<br />

This end of financial year event brought<br />

many old and new companies to view the<br />

latest developments in machine and tooling<br />

technology. Just three years since the<br />

opening of the £5 million refurbishment of<br />

their Technical Centre, AMADA has seen one<br />

of the most successful three day events in<br />

recent times. Orders concluded comprised of<br />

3 HG ATC (Press Brakes with Automatic<br />

Tool Changers), 6 Fibre Laser with various<br />

automation and over 10 Press Brakes.<br />

Alan Parrott, Managing Director stated<br />

“It is great to see this number of people here,<br />

all of who have a real positive outlook for the<br />

future. Our new technology opens up huge<br />

opportunities for our customers to expand<br />

their businesses, and with the after sales<br />

support we offer they are very comfortable in<br />

taking that next investment step with<br />

AMADA”<br />

Tel: 01562 749500<br />

email: cathryn.morris@amada.co.uk<br />

SwifT-cuT<br />

auTomaTion<br />

creaTe global<br />

SparkS<br />

Swift-Cut Automation, the British designed<br />

and engineered CNC plasma cutting table<br />

manufacturer were thrilled when Dr Liam Fox<br />

and the Department for International Trade<br />

officially opened their new factory, offices and<br />

demo suite. During his visit, he spent some<br />

time discussing Swift-Cuts growing success in<br />

the international export market.<br />

Since Swift-Cut’s inception in 2011 the<br />

export figure was zero, fast forward six years<br />

and Swift-Cut now exports over 80% of its<br />

products globally. Working closely with the<br />

Department of Trade they have opened<br />

channel partners in 26 countries and with the<br />

continued support of the government are now<br />

successfully expanding into the United States<br />

of America. Dr Fox said, ‘Swift-Cut is exactly<br />

the sort of company we need to be replicating<br />

across the UK’.<br />

With such a growing global presence<br />

Swift-Cut are flying the flag for British<br />

manufacturing and export making it<br />

abundantly clear that the UK is very much<br />

‘open for business’. During the visit, the<br />

Trade Secretary outlined the further support<br />

and expertise available to help Swift-Cut<br />

achieve the main company target - to be the<br />

global brand leader of value engineered CNC<br />

cutting solutions.<br />

With this growth comes expansion and<br />

Swift-Cut are keen to build on their success by<br />

creating more jobs and apprenticeship<br />

opportunities. Investment in innovation,<br />

technology and people has always been<br />

integral to Swift-Cut, never more so than now<br />

when export is at an all-time high and Swift-<br />

Cut strive to create a market for new products.<br />

The emphasis on the quality of<br />

manufacturing of a standard product and its<br />

place in the global market means that the<br />

business scalability of Swift-Cut is<br />

immeasurable. Looking around the Swift-Cut<br />

facilities in Burton-on Trent, Dr Fox said,<br />

‘success stories like Swift-Cut Automation are<br />

flying the flag for British quality and expertise,<br />

bringing a boost to their local economies.’<br />

Tel: 01543 473300<br />

web: www.swiftcut.co.uk<br />

8 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

There’s no shadow of a doubt<br />

that our advanced Duratomic ®<br />

inserts help automotive<br />

manufacturers machine steel<br />

and cast iron components more<br />

productively, efficiently and<br />

economically than ever before.<br />

Furthermore, because our TP<br />

insert grades (for steel) and our<br />

TK insert grades (for cast iron)<br />

both feature our Used Edge<br />

Detection innovation - you’ll be<br />

able to see the difference they<br />

make to your performance and<br />

profitability in next to no time.<br />

WWW.SECOTOOLS.COM/GB<br />

DURATOMIC ® INSERTS -<br />

WHAT WILL YOU MAKE<br />

WITH YOURS?

10 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

High Tech 5 Axis Universal and Gantry Milling Machines<br />

Dugard are the Exclusive UK Dealers of<br />

Werkzeugmaschinen<br />

EDEL Multimill 1000 / 1600<br />

• 1000mm / 1600mm diameter tables<br />

• 5 axes milling - Heidenhain or<br />

Siemens controls<br />

• Turning option<br />

• Automatic pallet exchanger<br />

(option on Multimill 1000)<br />

• Easy machine access<br />

EDEL Multimill 1600<br />

EDEL Multimill 1000<br />

3 & 5 Axis Gantry Mills with up to 10m X Travel also Available<br />

EDEL Rotamill 22<br />

• 1800mm diameter table<br />

• Spindles 27~50kW<br />

• 5 / 6 axes<br />

• Milling, turning and grinding<br />

all in one machine<br />

• Automatic head exchange<br />

• Easy machine access<br />

EDEL Rotamill 22<br />

Machine<br />

DUGARDTools<br />

On show at the<br />

DUGARD<br />

Open House<br />

13,14,15 June<br />

www.dugard.com sales@dugard.com 01273 732286

NEWS NEWS NEWS<br />

kerf Cuts a Bright future for<br />

sCottish steel working CompanY<br />

Evolving from a small blacksmiths to a 1.5 acre<br />

site, John Thorburn & Sons Ltd has grown<br />

beyond recognition during its 70 year history.<br />

The family run business that specialises in the<br />

construction, agriculture and commercial steelworking<br />

sectors has always invested in the<br />

latest technology to underpin its continuous<br />

growth. This investment has now seen the<br />

Scottish company invest in an UltraSharp<br />

plasma cutting machine from Rochdale based<br />

Kerf Developments.<br />

Employing over 50 staff that operate a<br />

variety of turning and milling centres as well as<br />

punching, pressing, fabricating and guillotine<br />

equipment, the modern-day business primarily<br />

manufactures, fabricates and erects agricultural<br />

buildings and structures. To manufacture the<br />

numerous components that constitute a<br />

complete steel building structure, Duns based<br />

John Thorburn & Sons relied upon its guillotine,<br />

punching, steel working and fabricating<br />

equipment until the arrival of a Kerf RUR2500<br />

plasma cutting machine.<br />

Commenting on why the company bought<br />

the Kerf RUR2500, Managing Director and<br />

XYZ Machine Tools has announced the<br />

appointment of Howard Bamforth to the role of<br />

Export Sales Director, with the key focus of<br />

developing the potential for XYZ’s range of<br />

ProtoTRAK controlled mills and lathes and<br />

CNC turning and machining centres across<br />

Europe, Africa and the Middle East.<br />

With 28 years’ experience in the machine<br />

tool business, including time working on<br />

machine design and development , project<br />

engineering, customer service/satisfaction and<br />

sales, both through distribution and direct with<br />

customers, Howard is excited at the<br />

opportunity to take the XYZ brand to a wider<br />

audience and increase sales in these export<br />

markets.<br />

“Coming from a more restrictive<br />

environment, it is a refreshing change to join<br />

XYZ Machine Tools with a management<br />

structure that allows quick decision making in<br />

order to meet customer and market demands.<br />

With the extensive and well respected range of<br />

machines on offer from XYZ this is a job that I<br />

am looking forward to getting my teeth into. I<br />

will be maximising my 20 plus years of<br />

experience dealing with European distribution<br />

grandson of company founder John Thorburn<br />

Snr, Mr John Thorburn says: "We recognised<br />

that our method of cropping, punching and<br />

drilling plates was cumbersome, time<br />

consuming and slowing down our throughput.<br />

All our jobs had to be handled and re-worked<br />

on a variety of different machines to arrive at a<br />

finished part. Additionally, we had to stock a<br />

large range of steel bar widths and thicknesses<br />

and this was taking a lot of floor space. Kerf has<br />

instantly eliminated all of these issues."<br />

John Thorburn & Sons investigated the<br />

various options and it arrived at the conclusion<br />

that Kerf Developments had the most suitable<br />

solution for its needs. The Berwickshire<br />

business specified the RUR2500 with a 6m by<br />

2m bed, so it could comfortably fit 4m by 2m by<br />

20mm thick plate on the machine. This bed<br />

capacity enables the company to use the nesting<br />

facility on the Kerf machine to cut up to 50<br />

stanchion base plates in a single set-up.<br />

As a result of acquiring the Kerf UltraSharp<br />

plasma machine, the Scottish company has<br />

streamlined production, reduced steel<br />

stockholding, freed machine tool and labour<br />

capacity and also reduced material and<br />

consumable costs. As a result of releasing this<br />

extra capacity, the company has now started<br />

offering subcontract cutting services as well as<br />

targeting a wider variety of work in its core<br />

market segments.<br />

tel: 01706 757 670<br />

email: sales@kerfdevelopments.com<br />

web: www.kerfdevelopments.com<br />

XYZ strengthens eXport sales<br />

with keY appointment<br />

and the relationships that I have developed, as I<br />

am a great believer in the fact that people buy<br />

from people. I am under no illusion that this<br />

isn’t a tough challenge, but it is one that I am<br />

relishing,” says Howard Bamforth.<br />

Howard joins XYZ at an exciting time for the<br />

company with new machines being introduced<br />

and the company just concluding what looks<br />

like being its seventh consecutive year of record<br />

sales. “As we embark on a new chapter for XYZ<br />

with our first simultaneous five-axis machine,<br />

along with other new developments in <strong>2017</strong>,<br />

our growth of export sales will play a major role<br />

in the continuing success of XYZ.<br />

tel: 01823 674200<br />

email: nigel.atherton@xyzmachinetools.com<br />

web: www.xyzmachinetools.com<br />

welding<br />

automation<br />

solves CapaCitY<br />

proBlem<br />

ESAB has supplied an automated welding<br />

system to EWP Windtower Production AB for<br />

making longitudinal welds in sections of wind<br />

turbine towers. The highly efficient submerged<br />

arc welding system comprises a CaB 460C<br />

column-and-boom that manipulates a tandem<br />

single + twin welding head, with a FFRS Super<br />

flux feed and recovery system complete with<br />

heaters and filter unit; power comes from three<br />

ESAB Aristo 1000 welding power sources and<br />

control is via ESAB PEK controllers<br />

complemented by a GMH automatic jointtracking<br />

system. In addition to this equipment,<br />

EWP Windtower Production AB is also using<br />

ESAB consumables, namely OK Autrod 12.22<br />

copper-coated, unalloyed welding wire and OK<br />

Flux 10.71 agglomerated basic flux.<br />

EWP Windtower Production needed to<br />

increase capacity in its factory in Landskrona,<br />

Sweden for manufacturing wind turbine<br />

towers, so the company decided to automate<br />

the welding of longitudinal seams on the<br />

smaller-diameter sections by installing a<br />

column-and-boom submerged arc welding<br />

system. Tenders were invited from prospective<br />

suppliers and the contract was won by ESAB<br />

due to its technical capability, the welding<br />

system’s performance specification and<br />

reliability, a short lead time and competitive<br />

pricing. EWP Windtower Production has used<br />

ESAB equipment for 15 years and was confident<br />

that the new CaB welding system would be<br />

reliable and, should the need arise, ESAB could<br />

be depended on for technical support in relation<br />

to the equipment and welding process.<br />

tel: 0800 389 3152<br />

email: info@esab.co.uk<br />

12 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

igus ® dry-tech ® ... lubrication-free bearings made easy<br />

Linear<br />

treasure<br />

chest<br />

!"!#<br />

<br />

<br />

<br />

<br />

SubconDrillingLtd<br />

Gundrilling - Honing - CNC Machining - Superfinishing<br />

Subcon Drilling Limited is a highly professional<br />

company whose entire experience and energy is<br />

focused solely on Gun Drilling, Deep Hole Drilling,<br />

Honing, CNC Machining and Superfinishing.<br />

With the knowledge and extensive experience<br />

of over 30 years, Subcon Drilling continually<br />

provides a professional and personal approach<br />

with total dedication to quality to a list of long<br />

serving clients.<br />

Our BS EN ISO9001:2008 Quality Management<br />

System is an integral part of our business. Focused<br />

on quality, Subcon Drilling is recognised<br />

as the leading Gun drilling and specialist machining<br />

is recognised as the leading Gun drilling<br />

and specialist machining provider in the U.K.,<br />

continually meeting and exceeding our<br />

customer’s demands.<br />

Lubrication-free technology and the largest linear toolkit ...<br />

design freedom ... no oil ... low-cost. drylin ® W: linear bearings<br />

for quiet and easy operating, insensitive to dust and dirt.<br />

Configured and installed quickly and easily. From single<br />

bearings to linear actuators and 3 axis linear robots. Low<br />

cost, delivery time from 24 h. www.lineartoolkit.co.uk<br />

Subcon Drilling Ltd<br />

Unit 6, The Heron Business Park, Eastman Way, Hemel Hempstead, Hertfordshire HP2 7FW<br />

Tel: 01442 205960 Fax: 01442 205961<br />

www.subcondrilling.co.uk Email: dean@subcondrilling.co.uk<br />

igus ® Caswell Road<br />

Northampton NN4 7PW<br />

plastics for longer life ®<br />

Tel 01604 677240<br />

sales@igus.co.uk<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong> 13

Among all of the UK’s major machining<br />

sectors, tool and mouldmaking has probably<br />

witnessed the most reshoring in recent years.<br />

Quality concerns, the time difference and the<br />

language barrier between the UK and places<br />

such as the Far East have led many to<br />

concede defeat and return mould and die<br />

manufacturing to Britain and other countries<br />

in Western Europe.<br />

This is one of the major reasons why<br />

investment in the latest EDM technology<br />

remains strong. A case in point can be seen at<br />

a UK die-casting shop that has acquired a<br />

new Sodick AG40L die-sinking machine from<br />

Sodi-Tech EDM. Installed at the company’s<br />

recently-expanded toolroom facility, the<br />

machine is not only 10 times faster than the<br />

outdated EDM machine it replaced, but offers<br />

far better surface finish and accuracy.<br />

“Our previous die sink EDM had become<br />

slow and unreliable,” states Grant Weedon,<br />

toolroom director at Wadebridge-based<br />

Daften Die-Casting. “We considered a<br />

variety of potential replacements, but the<br />

Sodick AG40L was affordable and came<br />

equipped with a tool-changer and fire<br />

extinguishers as standard. Furthermore the<br />

extensive support provided by Sodi-Tech<br />

was highly recommended.”<br />

The AG40L has been set to work<br />

producing cores and cavities for die-casting<br />

tools, as well as some prototyping projects.<br />

Tools produced by Daften are destined for<br />

industries that include the pump,<br />

telecommunications, lighting and audio<br />

sectors, to list but a few.<br />

“In essence, we are using the AG40L to<br />

eliminate the need for milling complex<br />

tooling parts to extremely tight tolerances,”<br />

says Grant Weedon. “The finish we are<br />

achieving is amazing, as is the accuracy –<br />

we’ve never held 0.01mm on a die sink EDM<br />

before. In addition, I would estimate that<br />

Sodick machine is 10 times faster than our<br />

previous model, which means we have<br />

gained extra capacity. Ultimately, we have<br />

bought this machine to make our tools inhouse,<br />

instead of buying them from China. It<br />

gives us much greater control over the whole<br />

process, which is definitely in the best<br />

interests of our customers.”<br />

Using new investment to underpin<br />

business success can also be seen at<br />

Aesculap, a division of the B Braun group<br />

that specialises in all areas of surgical,<br />

orthopaedic and interventional patient care.<br />

In the mouldmaking department of the<br />

company’s headquarters in Tuttlingen,<br />

Germany, Aesculap machines complex<br />

moulds, which are then transferred to its<br />

facility in Penang, Malaysia for the<br />

production of plastic parts.<br />

EDM MOULD & DIE<br />

DO OR DIE<br />

“All from a single source,” was the aim of<br />

Hans Keller when it came to the decision to<br />

buy a fully-automated Exeron production<br />

cell (Exeron machines are available in the UK<br />

from CNC International). Driving the<br />

investment was the development of plastic<br />

screw clips for sealing blood vessels, which<br />

require magazines that are supplied in<br />

different sizes. For an injection mould, a total<br />

of 70 electrodes are necessary. As a result,<br />

Aesculap invested in the new production<br />

cell, which comprises: an Erowa rotary<br />

changing station with space for 90 electrodes<br />

and 10 workpiece pallets; an Exeron EDM312<br />

eroding machine; an Exeron HSC300 milling<br />

machine; a Zeiss Duramax measuring<br />

machine; and an ERSL linear robot. During<br />

eroding, the company works with accuracies<br />

in the realm of ±0.01mm. Therefore, and<br />

because of the many electrode changes,<br />

Aesculap decided to pursue full automation.<br />

The automotive sector is also driving<br />

investment levels at mould and die shops, as<br />

Bergamo, Italy-based Aldeghi Srl can testify.<br />

Automotive components are getting<br />

smaller and smaller. Here, the convergence<br />

of automotive and ICT contribute to<br />

miniaturisation and drive the evolution of<br />

tighter tolerances for moulds. This trend<br />

extends to clearances for sliding components<br />

and ejectors, and angles for sliders, for<br />

example.<br />

Aldeghi relies on EDM products from GF<br />

Machining Solutions. In total, the company’s<br />

fleet includes eight wire EDM machines: one<br />

AgieCharmilles CUT 200 mS, two CUT 300<br />

mS, two Robofil 4030 SI, and one each of the<br />

Robofil 2030 SI, Robofil 6030 SI TW and<br />

Robofil 2050 TW. Six of these machines are<br />

equipped with System 3R WorkPal palletchanging<br />

robots.<br />

To ramp up the firm’s taper-cutting<br />

accuracy and surface quality, the company<br />

has recently invested in GF Machining<br />

Solutions’ Taper-Expert. This takes<br />

advantage of the Quadrax design on the two<br />

CUT 300 mS machines to allow precise<br />

machining of tapers with angles varying<br />

from 0 to 45 degrees. In real time, this<br />

optional GF Machining Solutions’ module<br />

corrects the wire position, depending on the<br />

angle, without sacrificing surface quality.<br />

Aldeghi also relies on GF Machining<br />

Solutions’ thermo-stabilisation technology to<br />

help defeat temperature fluctuations.<br />

Of course, demand for advanced EDM<br />

technology is such that development<br />

continues apace at the major vendors. Now<br />

available from Warwick Machine Tools, for<br />

example, is the new range of ONA AV wire<br />

EDM machines. The series includes two<br />

compact machines: the ONA AV25 with axis<br />

travels of 400 x 300 x 250mm in X, Y and Z;<br />

and the larger ONA AV35 model, with<br />

travels of 600mm in X, and 400mm in Y and<br />

Z. Both have U-V travels of 120 x 120mm. The<br />

layout of these two models has reduced the<br />

installed floor space by around 20%<br />

compared with existing machines of similar<br />

dimensions, says ONA.<br />

Using a modular design concept, the<br />

larger-scale AV machines in the range are<br />

designed for the wire cutting of bulky<br />

components. These start with the ONA<br />

AV60, with cutting speeds of up to<br />

450mm2/min, and move up to the AV130,<br />

which can accept loads up to 10,000kg on the<br />

work-table.<br />

Elsewhere, Fanuc has announced a<br />

milestone, recently producing its 30,000th<br />

Robocut wire EDM, which first started<br />

production in 1975. The latest technologies<br />

are available in the recently unveiled<br />

Robocut C-iB series, which now includes a<br />

newly-added model, the Robocut α-C800iB.<br />

This machine features a maximum cutting<br />

area of 800 x 600 x 500mm in the X, Y and Z<br />

axes, and a 3,000kg workpiece mass capacity.<br />

The reshoring of mouldmaking contracts<br />

to the UK marks a clear opportunity for<br />

British tooling shops to win new contracts.<br />

However, only by investing in the latest<br />

EDM technologies is possible to be at the<br />

front of the queue.<br />

14 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

Take the long view<br />

Sodick EDM - an investment for today and tomorrow<br />

A Sodick EDM LINEAR motor machine offers you a whole lot more<br />

More features, more functions, more benets....<br />

All Sodick EDM machines incorporate LINEAR DRIVE TECHNOLOGY<br />

providing our customers with the benets of higher accuracy with zero backlash<br />

and a smoother surface nish. We also include, as standard, all Sodick’s<br />

trademark features, such as ceramic components, user-friendly software and<br />

error-free data conversion. In addition, and to ensure our customers’ complete<br />

peace of mind, we provide our unique 10-year ACCURACY WARRANTY.<br />

Sodi-Tech EDM sole UK distributor of Sodick EDM technology<br />

Rowley Drive, Baginton, Coventry CV3 4FG Tel. +44 (0)24 76 511 677 Email sales@sodi-techedm.co.uk www.sodi-techedm.co.uk

EDM MOULD & DIE<br />

What’S in thE<br />

pipElinE?<br />

Joint venture between GF Machining<br />

Solutions and GF Piping Systems<br />

demonstrates the power and potential of<br />

Additive <strong>Manufacturing</strong>.<br />

In injection moulding, the cooling time of a<br />

finished product can constitute up to 70 per<br />

cent of the cycle time. One reason that explains<br />

this situation is that in conventional mould<br />

making, temperature control or cooling<br />

channels can only be drilled in a straight line.<br />

As a consequence critical hotspots can often<br />

remain out of the coolant’s reach – and cannot<br />

be avoided…that is until now.<br />

Using Direct Metal Laser Sintering<br />

(DMLS) technology on the AgieCharmilles<br />

AM S 290 Tooling machine however makes it<br />

possible to integrate optimised, conformal<br />

cooling channels into the mould during the<br />

production process itself. This ensures faster<br />

and more even heat dissipation. It reduces<br />

thermal stress in the mould and prolongs<br />

service life. The plastic product quality and<br />

dimensional accuracy of the parts are also<br />

increased. In addition, this also allows for a<br />

drastic reduction in cycle times.<br />

In 2016 GF Machining Solutions<br />

collaborated with GF Piping Systems on a<br />

project to improve the quality of a plastic<br />

valve part used in the chemical industry.<br />

The project involved the use of GF<br />

Machining Solutions’ new Additive<br />

<strong>Manufacturing</strong> (AM) technology to solve a<br />

real life production issue - the objective being<br />

to use AM to create (build) metal mould<br />

inserts with integrated, intricate and<br />

optimally positioned conformal cooling<br />

channels to ensure improved part quality,<br />

quicker cycle times and reduced scrap rates.<br />

The GF Machining Solutions technology<br />

used in the project was an AgieCharmilles<br />

AM S 290 Tooling solution which<br />

incorporates powder bed-based laser<br />

sintering (DMLS) technology from the EOS<br />

M 290 system with necessary software,<br />

automation, secondary processing<br />

technologies (i.e. EDM, milling, laser<br />

texturing etc.), and measurement and<br />

inspection equipment.<br />

Web: www.gfms.com/uk<br />

thE qiMtEk blog<br />

The Contract <strong>Manufacturing</strong> Index (CMI) has been developed to reflect the total purchasing<br />

budget of companies that are looking to outsource manufacturing in any given month. This<br />

reflects a sample of over 4,000 companies, who have a purchasing budget of more than £3bn<br />

and a supplier base sample of over 7,000 vendors, with a verified turnover in excess of £25bn.<br />

Compared to the previous quarter, machining enjoyed a 26% increase in quarter 1;<br />

however, it is important to note that it is still 4% down on the 2016 average. Nonetheless, you<br />

may recall from our annual summary that the size of companies outsourcing machining - and<br />

thus, its index - fell dramatically over the course of last year. Therefore, the latest figures bode<br />

well for a more positive <strong>2017</strong>.<br />

The first quarter’s fabrication index is especially interesting, as it shows a 12% growth on<br />

the last quarter, as well as an impressive 8% rise in comparison to 2016’s average. Whereas<br />

machining experienced massive fluctuations last year, the fabrication index’s trajectory<br />

underwent a slow rise, albeit with large variations from month to month. Further increases<br />

within early <strong>2017</strong> are encouraging and will hopefully set the precedent for the coming year<br />

The results from the first quarter of <strong>2017</strong> reflect a buoyant fabrication and machining<br />

market, with healthy growth in both areas in comparison to the preceding quarter.<br />

Whilst the fabrication index continues to grow against its 2016 counterpart, machining is<br />

still behind despite a massive boost over the previous three months. This is largely due to the<br />

fact that the machining index followed a downward trajectory during the course of 2016 and<br />

is still in the process of recuperating to earlier levels.<br />

The results bear testament to the beginning of the oil & gas industry’s recovery after a<br />

period of decline. Whilst the electronics and industrial machinery sectors continue to flourish,<br />

food & beverage has slowed in spite of a thriving 2016.<br />

Web: www.qimtek.co.uk<br />

Sodick EdMS rEducE lEad-tiMES<br />

Rotadata, a Derby-based world leader in the<br />

provision of instrumentation for<br />

turbomachinery, has installed a new Sodick<br />

AD55L and a refurbished AQ35L EDM<br />

machine. Supplied by Sodi-Tech EDM, the<br />

two machines are set to help the company<br />

reduce lead-times and gain access to greater<br />

turnover without increasing head count.<br />

Moving towards the company’s 40th year<br />

within the turbomachinery industry,<br />

Rotadata provides full turnkey solutions<br />

from concept and consultation, through to<br />

full on-site installation and product testing<br />

support. As well as supplying pyrometry,<br />

telemetry, blade tip timing, blade tip<br />

clearance and traverse products, the<br />

company offers a range of advanced<br />

instrumentation and machining services to<br />

the turbine research/development and<br />

validation sector. Approximately 65% of its<br />

customers are from the aerospace industry,<br />

with the remaining 35% in power generation.<br />

The company has more than 100 clients in<br />

over 40 countries.<br />

“A typical machining project might see us<br />

take a civil turbine engine and produce all of<br />

the component holes and instrumentation<br />

required to run test, validation and<br />

development programmes,” explains<br />

Rotadata’s Managing Director Simon Taylor.<br />

“If we can help achieve just a 1%<br />

improvement in efficiency through our<br />

installations, it can potentially equate to<br />

customer savings worth millions of pounds.”<br />

This globally-renowned, ISO9001-<br />

approved SME says that its main competitors<br />

are the in-house resources of the major<br />

turbomachinery manufacturers, and that<br />

expanding its EDM capacity was a vital part<br />

of Rotadata maintaining its market<br />

advantage.<br />

Rotadata already had Sodick EDM<br />

machines on site, so the choice of supplier for<br />

the latest two machines was predetermined.<br />

“If you like a machine tool brand, don’t<br />

change, that’s our philosophy,” says Mr<br />

Taylor. “The linear motor technology on the<br />

Sodick machines is unrivalled for our<br />

applications, and their reliability has never<br />

been an issue. Furthermore, Sodi-Tech EDM<br />

are a supportive and professional partner.<br />

We knew we wanted the Sodick AD55L<br />

machine and a refurbished model also came<br />

up at the right time. It’s very rare to come<br />

across a pre-owned Sodick that is so new,<br />

because most people hang on to them. As a<br />

result, we jumped at the opportunity to buy<br />

these two additional machines.”<br />

tel: 0247 651 1677<br />

Email: sales@sodi-techedm.co.uk<br />

Web: www.sodi-techedm.co.uk<br />

16 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

Birchwood Close<br />

Forest Vale Industrial Estate, Cinderford, Glos. GL14 2PH<br />

Tel: + 44 1594 826779 Fax + 44 1594 826748 Web www.edm.co.uk<br />

EDM Sales & Services are recognised as the largest used machine<br />

dealership in the UK, specialising in high quality used<br />

wire erosion and spark erosion machines.<br />

1999<br />

Fanuc 1iA<br />

2000<br />

Form 20A<br />

2000<br />

Agie Classic 3<br />

2006<br />

Actspark SD1<br />

2005<br />

Robofil 440SL<br />

Fanuc<br />

Alpha Oia<br />

For further details of these machines and to view<br />

our full stock list please go to our website<br />

www.edm.co.uk<br />

1994<br />

Charmilles<br />

Roboform 40<br />

Over 10,000 parts / spares in stock<br />

2005<br />

Robofil 6050<br />

• WIRE<br />

• SINK<br />

• DRILLS<br />

• TAP REMOVER<br />

• SPARES<br />

• CONSUMABLES<br />

• TOOLING<br />

• SUB CONTRACT<br />

TEL: 01455 292002 WEB: www.eurospark.co.uk Email: sales@eurospark.co.uk<br />

TINBASHERS<br />

USED ROLLFORMERS,<br />

DECOILERS, LEVELLERS,<br />

CUT TO LENGTH AND<br />

SLITTING LINES<br />

FOR SALE OR WANTED<br />

CONTACT TOMMY SHEEHAN<br />

0789 984 7925 or 0161 429 8710<br />

Email: sales@tinbashers.com<br />

ON-LINE<br />

View the latest issue of<br />

http://machinery.world<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong> 17

maximising production<br />

reducing operating costs<br />

Wire & Die Sink EDM Technology Solutions<br />

Superior EDM<br />

machining<br />

solutions<br />

60 years providing solutions<br />

to the automotive<br />

industry<br />

A complete<br />

One Stop Shop<br />

from compact to<br />

customised EDM machines<br />

Tel: +44 (0)1676 534534 Email: sales@warwickmachinetools.co.uk<br />

Web: www.warwickmachinetools.co.uk<br />

JONES & SHIPMAN 1076EIU Cylindrical/Universal Grinder. Re-built<br />

by JONES & SHIPMAN in 2004 Well equipped inc. 2 Axis D.R.O.<br />

MYFORD MG12-HPM Plunge feed 1996<br />

MYFORD MG12-HP Plunge feed 1974<br />

MYFORD MG12-HP Plunge feed 1973<br />

MYFORD MG12-HM Semi Auto 1986<br />

MYFORD MG12-HA Semi Auto 1978<br />

MYFORD MG12-HA Semi Auto 1972<br />

MYFORD MG12-ME 1990<br />

MYFORD MG12-ME 1985<br />

MYFORD MG12-M 1990<br />

MYFORD MG12-M 1980<br />

MYFORD MG12-HPM Plunge feed 1996<br />

CHRISTEN 0.5-10 Drill Grinder 1990<br />

CHRISTEN 1-32 100A Drill Grinder 1990<br />

METEOR MM10 1994 Drill Grinder<br />

JONES & SHIPMAN 1077EIU<br />

1990 Cylindrical/Universal. DRO<br />

TRIPET MUR100 Internal Grinder<br />

ISOMA Type M128 Projector<br />

TECHNICA ZSM-5100 Centre Grinder<br />

CARL ZIESS Optical Dividing Head<br />

DELAPENA SPEEDHONE EA ELECTRONIC<br />

FILTERMIST FX6000 Air Mist Extractors x2<br />

DIAFORM: 5/1, 8/1, 8/2, 10/2, T.R.D.<br />

THE LARGEST SELECTION OF MYFORD MG12 SERIES GRINDERS IN THE WORLD!<br />

MYFORD MG12 SERIES OEM, SPARES, ACCESSORIES, ATTACHMENTS, MANUALS<br />

JONES & SHIPMAN Models in stock:<br />

1311, 1300, 1302, 1307, 1074, 1076, 1212, 1600, 310T, 540/ 540L Series, 1400/ 1400L/ 1400LAR<br />

See website for more pictures, specification and price<br />

MYFORD GRINDER SPARES<br />

JUBILEE MACHINE TOOLS<br />

T: 01332 348749 www.jubileemactools.com F: 01332 342416<br />

18 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

0121 54 11 444<br />

Mantechmachinery.com<br />

mantechmachinery@gmail.com<br />

SPECIAL PROMOTION<br />

SHEET METAL MACHINERY<br />

Including<br />

Fibre Lasers - Plasma Cutting Tables - Press Brakes -<br />

Guillotines - Folders<br />

3 Year Warranty on Selected Machines<br />

Support is Key!<br />

Full Coverage of the UK & Ireland by a team of<br />

fully qualified Service Engineers<br />

– Wherever you are, we are local to you!<br />

Should you require support on any hardware, software, design or<br />

operational issues our service department is second to none in<br />

response time. Our support team and mobile Service Engineers<br />

are available via phone or email 24/7.<br />

Information is Everything.<br />

Visit us in our 2000m 2 facility here in the Midlands where most of<br />

our machines are sold from stock. We can organise a<br />

demonstration and a technical meeting with our sales<br />

engineers to discuss all your requirements and application needs.<br />

Need a quotation?<br />

Please do not hesitate to contact us for a highly competitive<br />

quote. We can give an immediate quote for any machine.<br />

Our product range offers great value for money and<br />

prices are inclusive of installation, commissioning and training.<br />

All of our machines are fully warranted up to 3 years.

Suppliers of Quality<br />

Used Machine Tools<br />

WERA RM 80 CNC<br />

C/W SIEMENS CONTROL<br />

XYZ DPM CNC BED MILL<br />

C/W GUARDING<br />

AYCE<br />

HORIZONTAL BORER<br />

RICHMOND ENVOY<br />

RADIAL ARM DRILL<br />

COLCHSTER<br />

TORNADO T10<br />

HITACHI SEIKI CS 25<br />

TURNING CELL<br />

XYZ MINI MILL 560 C/W ATC AND<br />

SIEMENS CONTROL<br />

JONES & SHIPMAN 540 GRINDERS<br />

( 5 )<br />

MAZAK SQT 250M CNC LATHE<br />

WITH TOOLING<br />

HARRISON ALPHA 550 PLUS HARRISON ALPHA 330<br />

PLUS 1 MTR B/C<br />

WANTED SURPLUS MACHINES<br />

COLCHESTER TRIUMPH 2000<br />

REFURBISHED LATHE<br />

ADDISON CB 250 A BANDSAW<br />

COLCHESTER MASTIFF 80”<br />

FULLY REFURBISHED<br />

COLCHESTER T8MY<br />

CNC LATHE<br />

1302 JONES & SHIPMAN<br />

GRINDER

LED LIGHTING<br />

FOR<br />

INDUSTRIAL MACHINERY AT<br />

WWW.SECWORKLIGHTS.COM<br />

ARTICULATED LED LAMPS. LONG OR<br />

SHORT ARM TYPES. IP65<br />

FLEXIBLE NECK LAMPS.<br />

FIXED OR MAGNETIC BASE<br />

VARIOUS VOLTAGES.<br />

BRIGHT WHITE LIGHT.<br />

DESIGNED FOR USE<br />

INSIDE MACHINE<br />

ENCLOSURES<br />

AVAILABLE IN 12V AND 24V<br />

AC/DC AND 110-240VAC.<br />

STRIP LAMPS TO DIRECTLY REPLACE TUBE LAMPS. VARIOUS<br />

VOLTAGES, POWER AND LENGTHS. IP65<br />

CHECK WEBSITE FOR MORE DETAILS<br />

FROM<br />

£85.00 ex vat<br />

FREE UK DELIVERY.<br />

WEB: WWW.SECWORKLIGHTS.COM<br />

TEL: 07793 285 994<br />

EMAIL: steve@secservices.co.uk<br />

PRECISION SPINDLE<br />

REBUILDING<br />

We offer a complete rebuild service of CNC<br />

machining centre spindles, CNC lathe heads,<br />

Grinding spindles (both belt driven & high<br />

frequency types), Tailstocks, Fine boring<br />

spindles, Milling spindles, Centre-less<br />

grinding spindles, workheads, wheelheads etc.<br />

TECHNOVA PRECISION LTD<br />

Tel: 02476 366503 • Fax: 02476 361979<br />

Web: technovaprecision.com • Email: will@technovaprecision.com<br />

USED RIVETING MACHINE FROM<br />

THE MARKET LEADERS<br />

❋ MOST TYPES AVAILABLE<br />

❋ FULLY CHECKED<br />

❋ TOOLING<br />

❋ FIXTURING<br />

❋ GENERAL ADVICE<br />

❋ THOUSANDS OF MACHINES SOLD DURING<br />

OUR TWENTY FIVE YEARS IN BUSINESS<br />

CONTACT BILL CHALLENOR<br />

54 Coventry Road, Pailton,<br />

Rugby, Warwickshire CV23 0QB<br />

Tel: (01788) 833301 Fax: (01788) 833481<br />

Email: wgcrivet@gmail com<br />

Web Site: www.wgchallenor.co.uk<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong> 21

Exhibitors at Subcon, the UK’s only show<br />

dedicated to subcontract manufacturing, will<br />

be offering visitors a range of new services<br />

and capabilities following recent<br />

investments.<br />

Subcon, which runs from 6 to 8 June at the<br />

NEC, Birmingham, is the UK’s only event<br />

dedicated to outsourced manufacturing. It<br />

serves all sectors and all processes – from<br />

machining, sheet metalworking, casting and<br />

forging, to plastic moulding, composites and<br />

electronics.<br />

This range of manufacturing technologies<br />

is reflected in some of the new services and<br />

investments being featured at the show.<br />

In fabrication, WEC Group has invested<br />

over £11m in equipment and facilities over<br />

the last 18 months as the basis for its<br />

expansion nationwide, while multi-metal<br />

stockholder Kloeckner has just added<br />

advanced bending and additional laser<br />

cutting capacity to its services.<br />

Precision machining specialist PGT<br />

Ceewrite has also invested £11m to<br />

completely upgrade its Dorset facility and<br />

double its capacity for highly complex wire<br />

and spark erosion.<br />

The machining services sector is strongly<br />

represented across the show. New services<br />

coming on stream include a subcontract CNC<br />

cylindrical grinding facility at Perfect Bore<br />

and new large-format, heavy-duty<br />

machining centres at PRV. PRV has also<br />

added a new 5-axis water-jet cutting<br />

machine.<br />

The Advanced <strong>Manufacturing</strong> Show, which<br />

runs at the NEC from 6 – 8 June, is set to<br />

showcase a comprehensive complement of<br />

world-leading metrology companies.<br />

The Show features all aspects of advanced<br />

manufacturing technology – from machine<br />

tools and tooling, to work-holding, software,<br />

additive manufacturing and ancillary<br />

equipment – but has also come to be a<br />

biennial focus for the quality sector.<br />

Global brands including Hexagon<br />

<strong>Manufacturing</strong> Intelligence, Zeiss, Olympus<br />

and Alicona, are joined by UK champions<br />

including Renishaw and Aberlink, as well as<br />

specialists such as hire and contract scanning<br />

and measurement company Manchester<br />

Metrology, inspection, fixturing and<br />

calibration experts Verus, and<br />

representatives of world-leading equipment<br />

manufacturers such as Measurement<br />

Solutions.<br />

Together they cover all aspects of<br />

scanning, measurement and quality systems<br />

from contact and optical CMMs, to laser<br />

scanners, 3D surface measurement,<br />

WHATS ON SHOW<br />

fruitS of inveStMent on Show<br />

Following heavy investment in new<br />

technology, specialist subcontract<br />

engineering company Mini Gears Group<br />

expanded its services so that precision<br />

machining accounts for 60% of the business<br />

and it will be showcasing its complete new<br />

range of machined components at Subcon.<br />

In plastics, a five-year multi-million<br />

investment programme at Chess Plastics is<br />

nearing completion with the installation of<br />

another new Negri Bossi moulder and<br />

Meadex has just completed a new clean room<br />

suite for plastic and rubber moulding.<br />

Hepworth Group has launched a new RIM<br />

Moulding Division, which adds an<br />

additional manufacturing option to its<br />

extensive range of fabrication services.<br />

In other processes, Carlton Die Castings<br />

have installed a twin-pallet Mazak<br />

machining centre that allows them to supply<br />

fully-machined castings ready for assembly.<br />

Materials coatings expert NikaWorks has<br />

developed a new series of functional coatings<br />

for surgical instruments.<br />

Supporting the Subcon show, sourcing<br />

specialist Qimtek is sponsoring the VIP<br />

Buyer’s Programme and hosting a dedicated<br />

Qimtek UK <strong>Manufacturing</strong> Pavilion.<br />

Subcon runs alongside the Advanced<br />

<strong>Manufacturing</strong> Show and The Engineer<br />

Design & Innovation Show from 6 to 8 June<br />

<strong>2017</strong> at the NEC Birmingham.<br />

Together the three shows cover the<br />

complete manufacturing cycle from concept<br />

to component, bringing together design<br />

microscopy and automated systems.<br />

The show will feature some of the latest<br />

technology to hit the market, such as<br />

Aberlink’s Xtreme CNC CMM which uses a<br />

non-Cartesian structure and linear motors to<br />

maintain accuracy at very high measurement<br />

speeds.<br />

Advanced <strong>Manufacturing</strong> Show Event<br />

Director Gordon Kirk commented: “As we<br />

engineering, product development, in-house<br />

production and outsourced supply chains.<br />

Over 500 exhibitors will welcome<br />

thousands of professional visitors who have<br />

current sourcing needs for equipment,<br />

software and manufacturing services.<br />

The three shows are complemented by 36<br />

free-to-attend conference presentations in<br />

two separate conference streams, bought to<br />

you by The Engineer and The Manufacturer<br />

You can find out more about visiting and<br />

exhibiting at the three shows at:<br />

www.subconshow.co.uk ,<br />

www.advancedmanufacturingshow.co.uk<br />

and www.theengineerdesigninnovationshow.co.uk<br />

.<br />

AdvAnced MAnufActuring Show MeASureS up<br />

more further and faster along the track<br />

towards the Internet of Things, Big Data and<br />

Industry 4.0, metrology is the vital interface<br />

between the physical and digital worlds. It is<br />

therefore appropriate that it should be so<br />

well represented in an event focused on the<br />

leading edge of manufacturing technology.”<br />

The Advanced <strong>Manufacturing</strong> theme is<br />

emphasised in two conferences, The<br />

Engineer Conference and The Manufacturer<br />

Conference, which are free to attend for show<br />

visitors. Presentations by leading authorities<br />

in their fields cover subjects ranging from<br />

Industry 4.0, to additive manufacturing,<br />

novel materials and robotics.<br />

The Advanced <strong>Manufacturing</strong> Show runs<br />

in conjunction with The Engineer Design and<br />

Innovation Show and Subcon, the<br />

subcontract manufacturing show. Together<br />

the three shows cover the complete<br />

manufacturing cycle from design concept to<br />

finished product.<br />

for more information and to register for<br />

your free ticket please visit<br />

www.advancedmanufacturingshow.co.uk<br />

22 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

GET IN TOUCH<br />

01462 491919<br />

sales@floydautomatic.co.uk<br />

T H E T O O L I N G S P E C I A L I S T S F O R P R E C I S I O N C O M P O N E N T M A C H I N I N G<br />

FROM<br />

Ø1/8"<br />

THE NEW TYP0<br />

1/8" (3.20mm) OUTLET<br />

Ø1/4"<br />

PLUS THE NEW<br />

VARIO-JET<br />

PROGRAMABLE<br />

COOLANT NOZZLE<br />

Ø1/2"<br />

Ø3/4"<br />

The original SWISS made<br />

stainless steel adjustable and<br />

lockable coolant nozzle system<br />

Stable and reliable ow of<br />

coolant, oil or air. This includes<br />

standard applications of up to<br />

50 bar pressure, with optional<br />

components to go 100 bar plus.<br />

A permanent replacement for<br />

traditional plastic systems<br />

24 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

Association<br />

6-8 JUNE <strong>2017</strong> BIRMINGHAM NEC<br />

THREE CO-LOCATED EVENTS,<br />

THREE DAYS , ON E COMPLETE<br />

MAN UFACTURING SOLUTION<br />

THE GLOBAL PLATFORM<br />

FOR MANUFACTURING<br />

TECHNOLOGIES<br />

#AMSHOW17<br />

THE UK’S PREMIER<br />

SUBCONTRACTOR<br />

MANUFACTURING<br />

SUPPLY CHAIN SHOW<br />

#SUBCONSHOW<br />

FIRST FOR<br />

TECHNOLOGY &<br />

INNOVATION<br />

#TEDISHOW<br />

Three events, under one roof, will showcase the complete<br />

manufacturing solution; from product design, prototyping<br />

& development, contract and subcontract products and<br />

services through to machine tools, systems and equipment.<br />

Show Partner<br />

Q Qimtek<br />

Association Partners<br />

Composites<br />

Trade<br />

Media Partners<br />

REGISTER TO ATTEND FOR FREE<br />

WWW.SHOWS.THEENGINEER.CO.UK

Sole distributor for the UK and Ireland<br />

EASY CLAMPING<br />

WITH ONE WRENCH<br />

SUPER SLIM<br />

EDITION Ø 18 MM<br />

DIRECT CLAMPING<br />

OF UNIQUE SHANK<br />

Ø 3 MM AND BIGGER<br />

RUNOUT ACCURACY<br />

LESS THAN 0.003 MM<br />

AT 4XD<br />

Hydraulic Chuck Super Slim Type<br />

our answer to machining challenges<br />

26 <strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong>

are expanding<br />

Operating from a new 55,000 sq ft high-tech manufacturing facility<br />

enables us to react quickly and competently<br />

to the continuous changes in machining technology.<br />

Guhring Limited | Estone Drive | Aston Hall Road | Birmingham B6 6BQ | 0121 749 55 44<br />

GAUGES LTD<br />

PENICO ROTARY<br />

GRINDING TABLE<br />

• Converts surface grinders<br />

to rotary work<br />

• Robust construction<br />

For further details contact<br />

Penico Gauges Ltd<br />

Tel: 01274 511044<br />

Fax: 01274 510770<br />

Email:<br />

penicogauges@yahoo.co.uk<br />

Web: www.penico.com<br />

<strong>Machinery</strong> <strong>World</strong>, <strong>May</strong> <strong>2017</strong> 27

For small batch production<br />

Just In Time Production<br />

Fast automatic tool and gripper changing<br />

makes small batches protable<br />

Offline = Uptime<br />

Bespoke programming software<br />

allows fast program generation<br />

Low Labour Costs<br />

Automated program scheduling<br />

reduces labour costs<br />

Growing Together with Our Customers<br />

AMADA UK<br />

Tel: +44 (0) 1562 749 500<br />

Email: info@amada.co.uk<br />

www.amada.co.uk<br />

ANCA FASTGRIND TG7 CNC TOOL &<br />

CUTTER GRINDER New 1996 EQUIPPED<br />

WITH: Anca Fast Grind CNC Control Work<br />

Envelope X-Axis 13” (256 IPM) 108mm/s Y-<br />

Axis 9.5” (256 IPM) 108mm/s Z-Axis 8.2”<br />

(256 IPM) 108mm/s A-Axis £POA<br />

ANCA TG-4 4-AXIS CNC TOOL & CUTTER<br />

GRINDER New 1996 EQUIPPED WITH: Anca<br />

Fast Grind CNC Control CATALOGUE<br />